Hey there! As a supplier of alucobond wall panels, I often get asked about the standard thickness of these panels. It's a crucial question because the thickness can significantly impact the performance, durability, and cost of the panels. So, let's dive right in and explore what the standard thickness of alucobond wall panels is all about.

Understanding Alucobond Wall Panels

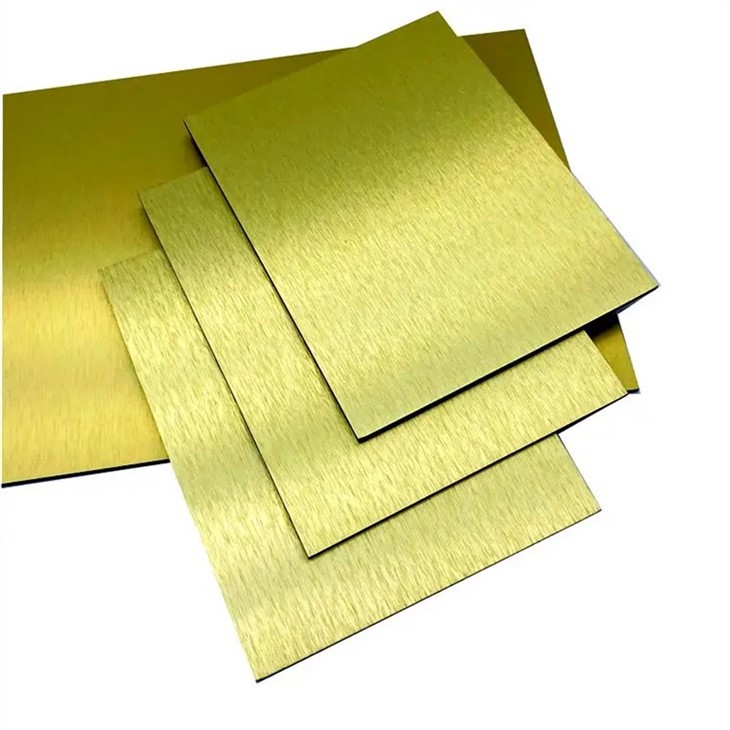

First off, let me give you a quick rundown on alucobond wall panels. These panels are made up of two aluminum sheets bonded to a polyethylene core. They're known for their lightweight yet sturdy construction, making them a popular choice for both interior and exterior applications. You can find them in a wide range of colors, finishes, and sizes, which makes them super versatile for different design projects.

Factors Affecting the Thickness

There isn't a one - size - fits - all answer when it comes to the standard thickness of alucobond wall panels. Several factors come into play when determining the right thickness for your project:

- Application: Are you using the panels for an interior partition or an exterior facade? Exterior applications usually require thicker panels to withstand harsh weather conditions, such as strong winds, rain, and UV rays. Interior applications, on the other hand, may allow for thinner panels as they're not exposed to the same level of wear and tear.

- Structural Requirements: The load - bearing capacity of the building and the overall structural design also influence the panel thickness. If the panels need to support a significant amount of weight or if they're part of a large - scale installation, thicker panels will be necessary.

- Aesthetic Preferences: Sometimes, the desired look of the project can affect the thickness choice. Thicker panels may give a more substantial and high - end appearance, while thinner panels can create a sleek and modern look.

Common Thicknesses

Typically, alucobond wall panels come in a range of thicknesses. The most common ones are 3mm, 4mm, and 6mm.

- 3mm Panels: These are the thinnest and lightest option. They're often used for interior applications like wall cladding in offices, shops, or residential buildings. They're also suitable for small - scale exterior projects where the panels don't need to bear a lot of stress. For example, they can be used for decorative accents on a building's facade. The Factory Brushed Surface Decorative ACP Panel is available in 3mm thickness and offers a great option for those looking for an affordable and stylish interior solution.

- 4mm Panels: This is the most widely used thickness for both interior and exterior applications. It strikes a good balance between cost, weight, and durability. 4mm panels can handle moderate wind loads and are suitable for medium - sized commercial buildings, apartment complexes, and even some high - end residential projects. The New Design Brushed Alucobond Panel in 4mm thickness provides a modern and durable option for various projects.

- 6mm Panels: These are the thickest and most robust panels. They're mainly used for large - scale exterior projects, such as high - rise buildings, industrial facilities, and structures in areas with extreme weather conditions. The extra thickness gives them better resistance to impact and deformation, ensuring long - term performance. If you're working on a project that requires top - notch quality and durability, the Top Quality ACP/ACM Aluminum Composite Panel Price in 6mm thickness is a great choice.

Industry Standards and Regulations

In addition to the factors mentioned above, industry standards and local building regulations also play a role in determining the appropriate thickness of alucobond wall panels. Different regions may have specific requirements regarding fire resistance, wind load resistance, and structural integrity. It's essential to check with your local building authorities and make sure the panels you choose comply with all the relevant standards.

Cost Considerations

Thicker panels generally cost more than thinner ones. The price difference is due to the additional materials used and the increased manufacturing complexity. However, it's important to look at the long - term cost rather than just the upfront price. Thicker panels may last longer and require less maintenance, which can save you money in the long run. When choosing the thickness, you need to weigh the cost against the benefits and the specific requirements of your project.

Installation and Maintenance

The thickness of the alucobond wall panels can also affect the installation process and maintenance requirements. Thicker panels may be more challenging to handle and install, as they're heavier and require more support. However, they also tend to be more stable once installed. Maintenance is usually straightforward for alucobond panels, regardless of the thickness. Regular cleaning with a mild detergent and water is usually sufficient to keep them looking good.

Making the Right Choice

So, how do you decide on the standard thickness for your alucobond wall panels? Here are some steps to help you make the right choice:

- Define Your Project Requirements: Clearly outline the application, structural needs, and aesthetic goals of your project.

- Consult with Experts: Talk to architects, contractors, or our team at [Supplier]. We have years of experience in the industry and can provide valuable insights and recommendations based on your specific situation.

- Consider the Budget: Determine how much you're willing to spend on the panels and factor in the long - term costs.

- Check Local Regulations: Make sure the panels you choose comply with all the relevant building codes and standards.

Conclusion

In conclusion, there isn't a single standard thickness for alucobond wall panels. The right thickness depends on a variety of factors, including the application, structural requirements, aesthetic preferences, and budget. By considering all these factors and consulting with experts, you can choose the perfect thickness for your project.

If you're interested in purchasing alucobond wall panels or have any questions about the thickness or other aspects of our products, don't hesitate to reach out. We're here to help you find the best solution for your project. Whether you need a 3mm panel for an interior design or a 6mm panel for a large - scale exterior construction, we've got you covered. Let's start a conversation and bring your project to life!

References

- Aluminum Composite Panel Association (ACPA)

- Local Building Codes and Regulations