Aluminum cladding panels have gained significant popularity in the construction and architectural industries due to their versatility, durability, and aesthetic appeal. As a trusted aluminum cladding panel supplier, I am often asked about the chemical composition of these panels. In this blog post, I will delve into the details of what makes up aluminum cladding panels, exploring their components and the role each plays in the panel's performance.

The Basics of Aluminum Cladding Panels

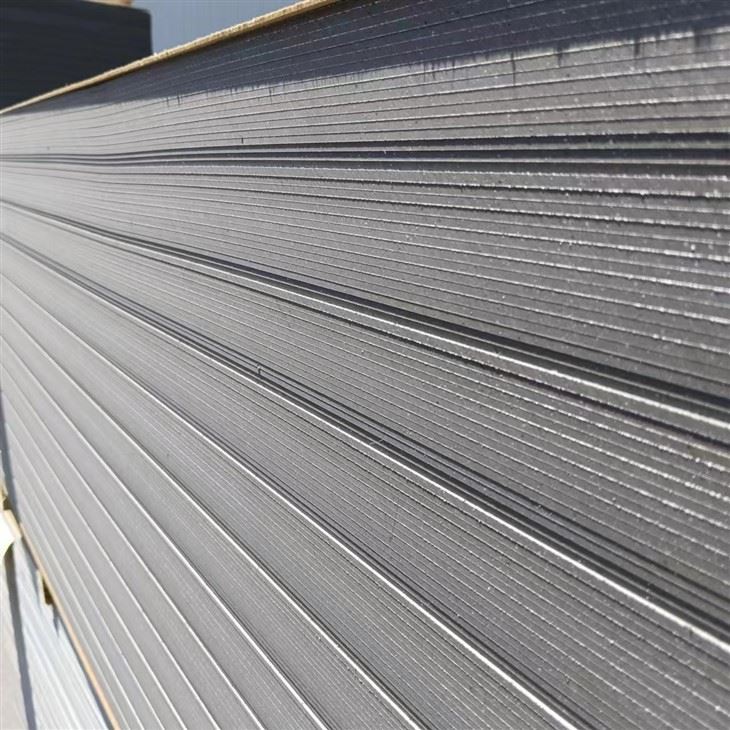

Aluminum cladding panels are composite materials typically consisting of two thin aluminum sheets bonded to a core material. This structure provides a balance of strength, lightweight properties, and design flexibility. The outer aluminum layers offer protection against environmental factors, while the core contributes to the panel's rigidity and insulation capabilities.

The Aluminum Layers

The outer aluminum layers are the most visible part of the cladding panel and play a crucial role in its appearance and performance. These layers are usually made from high - grade aluminum alloys, which are selected for their corrosion resistance, formability, and strength.

Aluminum Alloys

Aluminum alloys are mixtures of aluminum with other elements such as copper, magnesium, silicon, manganese, and zinc. The addition of these elements enhances the properties of pure aluminum. For example, copper can increase the strength of the alloy, while magnesium improves its corrosion resistance and weldability. The most commonly used aluminum alloys for cladding panels are from the 3xxx and 5xxx series.

The 3xxx series alloys, which contain manganese as the primary alloying element, offer good formability and moderate strength. They are often used in applications where the panels need to be bent or shaped during installation. On the other hand, 5xxx series alloys, with magnesium as the main alloying element, provide high strength and excellent corrosion resistance, making them suitable for exterior applications in harsh environments.

Surface Treatment

The surface of the aluminum layers is usually treated to enhance its appearance and durability. One of the most common surface treatments is anodizing. Anodizing is an electrochemical process that creates a protective oxide layer on the surface of the aluminum. This oxide layer is hard, wear - resistant, and provides excellent corrosion protection. It also allows for the coloring of the aluminum, giving designers a wide range of color options for the cladding panels.

Another popular surface treatment is painting. Paint coatings can provide additional protection against UV radiation, scratches, and chemical exposure. They also offer a greater variety of colors and finishes, including matte, gloss, and metallic effects. Some paint systems are designed to be self - cleaning, which helps to maintain the appearance of the cladding panels over time.

The Core Material

The core material of aluminum cladding panels is equally important as it determines many of the panel's physical properties, such as insulation, fire resistance, and soundproofing. There are several types of core materials used in aluminum cladding panels, each with its own advantages and disadvantages.

Polyethylene (PE) Core

Polyethylene is a thermoplastic polymer that is commonly used as a core material in aluminum cladding panels. PE cores are lightweight, flexible, and have good insulation properties. They are also relatively inexpensive, making them a popular choice for many construction projects. However, polyethylene is flammable, which can be a concern in some applications. To address this issue, some manufacturers produce fire - retardant PE cores by adding flame - retardant additives to the polymer.

If you are interested in PE - based aluminum composite panels, you can check out our Acp Alux Aluminum Composite Panel For Wall Cladding and Cheap Exterior/interior Wall Cladding Panel Aluminium Composite Panel.

Mineral - Filled Core

Mineral - filled cores are made by mixing inorganic materials such as magnesium hydroxide or aluminum hydroxide with a polymer binder. These cores offer improved fire resistance compared to PE cores. The inorganic fillers act as flame retardants, releasing water vapor when exposed to high temperatures, which helps to cool the panel and prevent the spread of fire. Mineral - filled cores also have good insulation and soundproofing properties, making them suitable for a wide range of applications, including commercial and residential buildings.

Fire - Retardant Core

Fire - retardant cores are specifically designed to meet strict fire safety regulations. They are often made from materials such as fiberglass, ceramic, or a combination of inorganic and organic materials. These cores have excellent fire - resistant properties and can prevent the spread of fire for an extended period. However, they are usually more expensive than PE or mineral - filled cores.

Adhesive Layer

The adhesive layer is used to bond the aluminum sheets to the core material. It plays a critical role in the structural integrity of the aluminum cladding panel. The adhesive must have good adhesion strength, durability, and resistance to environmental factors such as temperature changes, moisture, and UV radiation.

Epoxy - based adhesives are commonly used in aluminum cladding panels. Epoxy adhesives offer high strength and excellent chemical resistance. They can withstand a wide range of temperatures and are resistant to moisture, which helps to prevent delamination of the panel layers over time.

Protective Film

In addition to the main components, aluminum cladding panels often come with a protective film on the surface of the aluminum layers. This film is applied during the manufacturing process to protect the panels from scratches, dirt, and damage during transportation and installation.

Our New Protective Film For Aluminum Composite Panels is designed to provide long - lasting protection. It can be easily removed after the installation is complete, leaving the panels with a clean and smooth surface.

Conclusion

The chemical composition of aluminum cladding panels is a carefully engineered combination of aluminum alloys, core materials, adhesives, and surface treatments. Each component plays a specific role in the panel's performance, including its strength, durability, fire resistance, insulation, and aesthetic appeal.

As a supplier of aluminum cladding panels, we are committed to providing high - quality products that meet the diverse needs of our customers. Whether you are looking for a cost - effective solution with a PE core or a fire - resistant panel for a commercial building, we have the right product for you.

If you are interested in purchasing aluminum cladding panels or have any questions about our products, please feel free to contact us for a detailed discussion. We look forward to working with you on your next project.

References

- ASM Handbook Committee. (2001). ASM Handbook Volume 2: Properties and Selection: Nonferrous Alloys and Special - Purpose Materials. ASM International.

- Aluminum Association. (2019). Aluminum Design Manual. Aluminum Association.

- ASTM International. (2021). ASTM Standards for Aluminum and Aluminum Alloys. ASTM International.