Ensuring the flatness of aluminum composite material (ACM) during installation is crucial for achieving a professional and aesthetically pleasing finish. As a reliable aluminum composite ACM supplier, I understand the challenges that installers face and the importance of maintaining flatness throughout the installation process. In this blog post, I will share some valuable insights and practical tips on how to ensure the flatness of ACM during installation.

Understanding the Importance of Flatness

Flatness is not just about the visual appeal of the finished project; it also affects the structural integrity and durability of the ACM panels. Uneven surfaces can lead to stress concentrations, which may cause the panels to warp, crack, or delaminate over time. Additionally, a flat surface is essential for proper adhesion of the panels to the substrate, ensuring a long-lasting and secure installation.

Pre-Installation Preparation

Before you begin the installation process, it is important to conduct a thorough inspection of the ACM panels and the installation site. Here are some key steps to take:

- Inspect the Panels: Carefully examine each panel for any signs of damage, such as dents, scratches, or warping. If you notice any defects, set the panels aside and contact your supplier for a replacement.

- Check the Substrate: The substrate on which the ACM panels will be installed must be flat, smooth, and structurally sound. Use a straightedge or a laser level to check the flatness of the substrate. If the substrate is uneven, you may need to level it using a suitable leveling compound or by installing furring strips.

- Measure and Mark: Measure the dimensions of the installation area and mark the position of the panels on the substrate. Use a chalk line or a laser level to ensure accurate alignment.

Proper Handling and Storage

Proper handling and storage of the ACM panels are essential to prevent damage and maintain their flatness. Here are some tips to follow:

- Handle with Care: When handling the panels, use gloves to prevent fingerprints and scratches. Avoid dropping or dragging the panels, as this can cause damage.

- Store in a Dry Place: Store the panels in a dry, well-ventilated area away from direct sunlight and moisture. Stack the panels flat on a level surface to prevent warping.

- Protect from Impact: If the panels need to be transported, use a suitable vehicle or trailer with a flatbed. Secure the panels to prevent them from shifting or moving during transit.

Installation Techniques

The installation method you choose will depend on the type of ACM panels, the substrate, and the specific requirements of the project. Here are some common installation techniques and tips to ensure flatness:

- Adhesive Installation: Adhesive installation is a popular method for installing ACM panels. Apply a high-quality adhesive to the back of the panels and press them firmly onto the substrate. Use a roller or a trowel to ensure full contact between the panels and the substrate. Make sure to follow the manufacturer's instructions for the adhesive application and curing time.

- Mechanical Fastening: Mechanical fastening is another option for installing ACM panels. Use screws, rivets, or clips to secure the panels to the substrate. Make sure to use the appropriate fasteners for the type of panel and substrate. Drill pilot holes to prevent the panels from cracking or splitting.

- Joint Design: The design of the joints between the panels is important for maintaining flatness. Use a butt joint or a tongue-and-groove joint to ensure a tight fit between the panels. Make sure to leave a small expansion gap between the panels to allow for thermal expansion and contraction.

- Alignment and Leveling: Use a straightedge or a laser level to ensure that the panels are installed in a straight line and at the same level. Check the alignment and level of the panels frequently during the installation process and make any necessary adjustments.

Quality Control

Once the installation is complete, it is important to conduct a final inspection to ensure that the panels are flat and properly installed. Here are some key points to check:

- Flatness: Use a straightedge or a laser level to check the flatness of the panels. The panels should be within the specified tolerance for flatness.

- Alignment: Check the alignment of the panels to ensure that they are installed in a straight line and at the same level.

- Adhesion: Check the adhesion of the panels to the substrate by gently tapping on the panels with a rubber mallet. If you hear any hollow sounds, it may indicate poor adhesion.

- Sealing: Check the sealing of the joints between the panels to ensure that they are watertight and airtight. Use a suitable sealant to seal the joints.

Conclusion

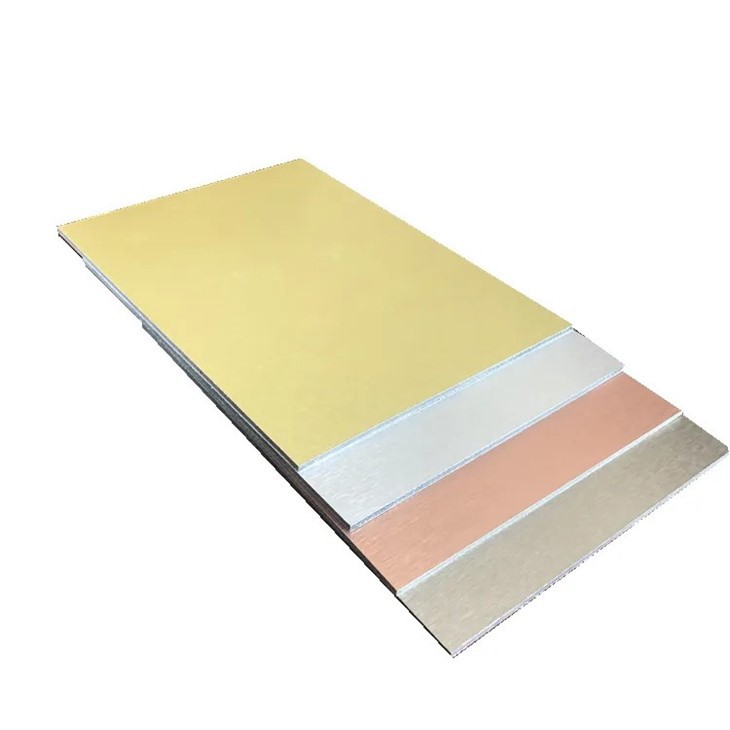

Ensuring the flatness of aluminum composite ACM during installation is essential for achieving a professional and long-lasting finish. By following the tips and techniques outlined in this blog post, you can minimize the risk of installation problems and ensure that your project looks its best. If you have any questions or need further assistance, please do not hesitate to contact us. As a leading supplier of Easy Install Aluminum Composite Panel Exterior Wall Advertising Manufacturers, Brushed ACP For Outdoor Advertising Board, and Top Quality ACP/ACM Aluminum Composite Panel Price, we are committed to providing our customers with high-quality products and excellent customer service. We look forward to working with you on your next project.

References

- Aluminum Composite Material Manufacturers Association. (n.d.). Installation Guidelines for Aluminum Composite Material. Retrieved from [Website URL]

- Manufacturer's Installation Instructions for [Specific ACM Product]. (n.d.). Retrieved from [Website URL]