Hey there! As a supplier of aluminum composite ACM, I often get asked about the maximum bending radius of this amazing material. So, I thought I'd sit down and share what I know about it.

First off, let's talk a bit about what aluminum composite ACM is. It's a panel made up of two aluminum sheets bonded to a non - aluminum core. This combination gives it a great balance of strength, durability, and flexibility. It's used in a wide range of applications, from building facades to interior decoration.

The maximum bending radius of aluminum composite ACM isn't a one - size - fits - all number. It depends on several factors. One of the most important factors is the thickness of the panel. Generally speaking, thicker panels have a larger minimum bending radius. For example, a thinner ACM panel, say around 3mm thick, can usually be bent with a relatively small radius. You might be able to bend it to a radius of about 100mm or so without causing any major damage to the panel. On the other hand, a 6mm thick ACM panel will need a larger bending radius, perhaps around 200mm or more.

The type of core material also plays a role. ACM panels can have different core materials, such as polyethylene (PE) or fire - resistant mineral cores. PE - cored panels are more flexible and can often be bent with a smaller radius compared to panels with fire - resistant cores. The fire - resistant cores are more rigid, which means they require a larger bending radius to avoid cracking or delamination.

Another factor is the quality of the bonding between the aluminum sheets and the core. A well - bonded panel can withstand more bending stress. If the bonding is weak, even a relatively large bending radius might cause the layers to separate. That's why at our place, we make sure to use high - quality adhesives and manufacturing processes to ensure a strong bond.

Now, let's talk about the importance of getting the bending radius right. If you try to bend an ACM panel with a radius that's too small, you'll run into some problems. The most obvious one is that the panel might crack. This not only looks bad but also weakens the panel's structural integrity. Cracks can also allow moisture to seep in, which can lead to corrosion over time. Delamination is another issue. When the aluminum sheets separate from the core, the panel loses its strength and becomes less useful.

On the flip side, using a bending radius that's too large might not be practical for your project. You might end up with a shape that doesn't fit your design requirements. So, it's all about finding that sweet spot.

When it comes to bending ACM panels, there are different methods. One common method is cold bending. This involves using mechanical tools to bend the panel at room temperature. It's a simple and cost - effective way, but it requires some skill to get the radius just right. Another method is hot bending. In hot bending, the panel is heated to a certain temperature to make it more pliable. This allows for more precise bending and can sometimes achieve smaller bending radii. However, hot bending requires specialized equipment and careful control of the temperature to avoid damaging the panel.

As a supplier, we've seen a lot of different projects that use bent ACM panels. Some architects and designers are really creative and come up with some amazing curved shapes for building facades. For example, a modern office building might have a gently curved facade made from ACM panels. To achieve that smooth curve, they need to calculate the right bending radius based on the panel's specifications.

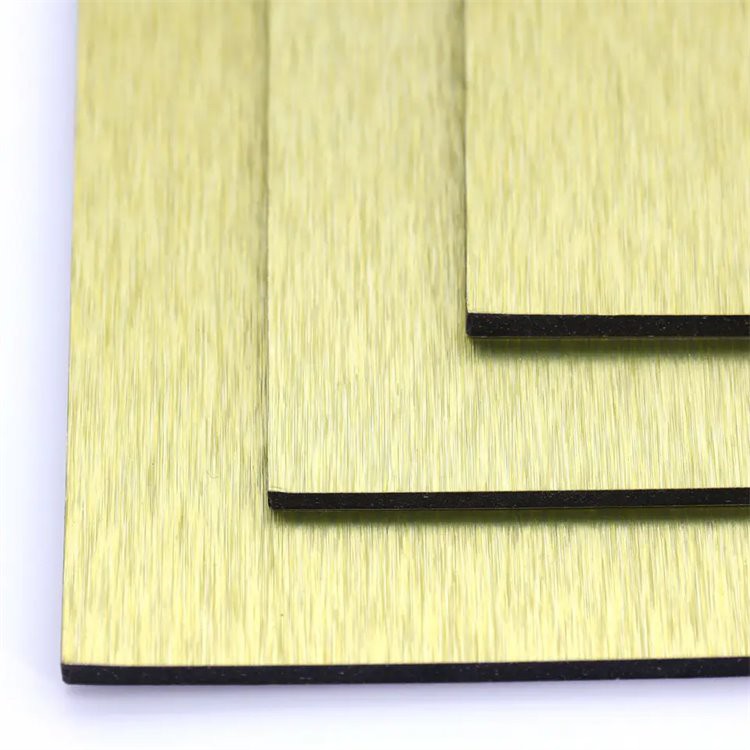

If you're in the market for ACM panels for a project that involves bending, we've got a great selection. Check out our Alternative Wall Materials Black Brushed Aluminium Composite Panel. It's a really stylish option that can add a modern touch to any building. We also have the New Design Brushed Alucobond Panel, which has a unique brushed finish that looks great when bent into different shapes. And for a more luxurious look, our Gold Brush ACP Cladding Sheet is a top - notch choice.

We're here to help you every step of the way. Whether you need advice on the maximum bending radius for your specific project or you're just looking for the right type of ACM panel, our team of experts is ready to assist. We can provide you with technical data sheets that give you all the information you need about the bending capabilities of our panels.

If you're interested in working with us, we'd love to have a chat. Just reach out to us and we can start discussing your project requirements. We can offer you competitive prices and high - quality products that meet your standards. So, don't hesitate to get in touch and let's create something amazing together!

References

- Architectural Aluminum Composite Panel Handbook

- Industry research on Aluminum Composite Material Properties