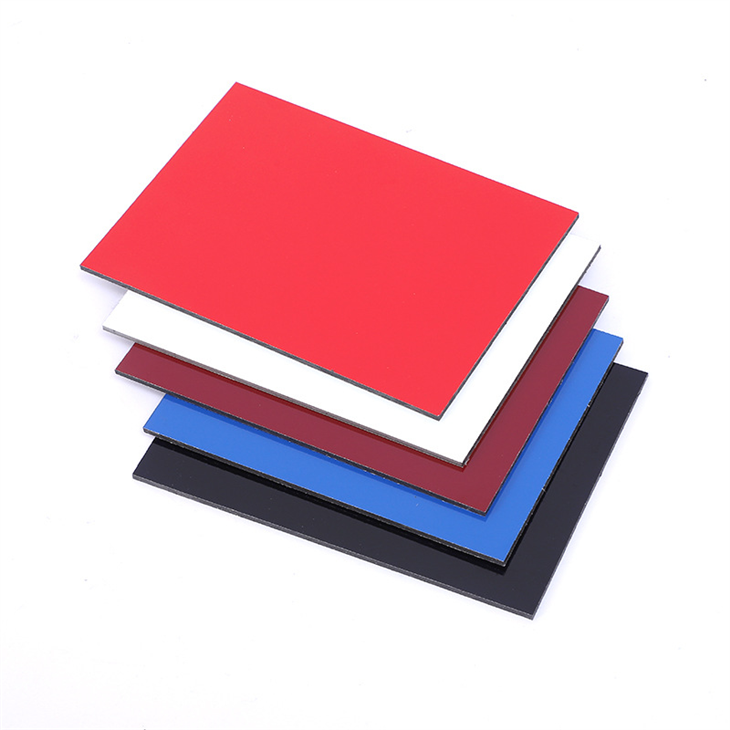

Fatigue resistance is a critical property for materials used in various applications, especially in industries where components are subjected to cyclic loading. As a leading supplier of aluminium composite sheets, I understand the importance of fatigue resistance in ensuring the long - term performance and durability of our products. In this blog, we'll delve into what fatigue resistance of aluminium composite sheets is, its influencing factors, and why it matters for different applications.

Understanding Fatigue Resistance

Fatigue resistance refers to a material's ability to withstand repeated loading and unloading cycles without failing. When a material is under cyclic stress, small cracks can initiate and propagate over time. Eventually, these cracks can grow large enough to cause the material to break or fail. For aluminium composite sheets, which are widely used in building facades, signage, and transportation industries, fatigue resistance is crucial as they are often exposed to dynamic forces such as wind, vibrations, and temperature fluctuations.

Factors Affecting the Fatigue Resistance of Aluminium Composite Sheets

Material Composition

The base materials of aluminium composite sheets play a significant role in their fatigue resistance. Aluminium is known for its good corrosion resistance and relatively high strength - to - weight ratio. The core material, which can be made of polyethylene, mineral - filled core, or other substances, also affects the overall fatigue performance. For example, a mineral - filled core may provide better stiffness and resistance to deformation under cyclic loading compared to a polyethylene core.

Manufacturing Process

The manufacturing process of aluminium composite sheets can greatly influence their fatigue resistance. Proper bonding between the aluminium skins and the core is essential. Any defects in the bonding process, such as air bubbles or uneven adhesion, can act as stress concentration points, leading to premature crack initiation. Advanced manufacturing techniques ensure a uniform and strong bond, enhancing the overall fatigue performance of the sheets.

Surface Treatment

Surface treatments like PVDF (Polyvinylidene Fluoride) coating can improve the fatigue resistance of aluminium composite sheets. PVDF coating not only provides excellent weather resistance but also enhances the surface hardness of the sheets. This can help prevent surface damage from environmental factors and minor impacts, which could otherwise lead to crack initiation. For instance, our 4*0.21mm PVDF Aluminum Composite Panel Wall Cladding with high - quality PVDF coating offers enhanced fatigue resistance and long - term durability.

Importance of Fatigue Resistance in Different Applications

Building Facades

In building facades, aluminium composite sheets are exposed to continuous wind forces, which can cause cyclic stress on the panels. High fatigue resistance ensures that the panels can maintain their structural integrity over the long term, preventing premature failure and ensuring the safety of the building. Our 4'x8' Aluminum Composite Panel is designed to meet the demanding requirements of building facades, with excellent fatigue resistance to withstand the ever - changing environmental conditions.

Signage

Signage made from aluminium composite sheets is often subject to vibrations from wind and traffic. Fatigue resistance is vital to ensure that the signs remain intact and visually appealing over time. A sign with poor fatigue resistance may develop cracks or deformations, reducing its effectiveness and aesthetic value. Our aluminium composite sheets provide reliable performance for signage applications, helping businesses maintain a professional and lasting image.

Transportation Industry

In the transportation industry, aluminium composite sheets are used in interior and exterior components of vehicles. These components are exposed to vibrations from the vehicle's movement, as well as dynamic forces during acceleration and braking. Good fatigue resistance is necessary to ensure the safety and reliability of these components. Our Outdoor Aluminum Composite Panel PVDF Coating is suitable for transportation applications, offering high - performance and long - lasting solutions.

Testing the Fatigue Resistance of Aluminium Composite Sheets

To ensure the fatigue resistance of our aluminium composite sheets, we conduct a series of rigorous tests. One common test method is the cyclic loading test, where the sheets are subjected to a specific number of loading and unloading cycles at a defined stress level. The test specimens are closely monitored for crack initiation and propagation. Non - destructive testing methods, such as ultrasonic testing and X - ray inspection, are also used to detect any internal defects that may affect the fatigue performance.

Improving Fatigue Resistance

There are several ways to improve the fatigue resistance of aluminium composite sheets. As mentioned earlier, proper material selection and manufacturing processes are fundamental. Additionally, optimizing the panel design can also enhance fatigue performance. For example, reducing sharp corners and edges in the panel design can minimize stress concentration. Reinforcing the panels at critical areas can also help distribute the stress more evenly, reducing the risk of crack initiation.

Conclusion

Fatigue resistance is a key property of aluminium composite sheets that determines their long - term performance and durability in various applications. As a supplier, we are committed to providing high - quality aluminium composite sheets with excellent fatigue resistance. Our products are designed and manufactured using the latest technologies and materials to meet the strict requirements of different industries.

If you are interested in our aluminium composite sheets and want to learn more about their fatigue resistance or other properties, please feel free to contact us for procurement and further discussions. We look forward to working with you to find the best solutions for your projects.

References

- Smith, J. K. (2018). Fatigue of Metal Structures. CRC Press.

- Davis, J. R. (2001). Aluminum and Aluminum Alloys. ASM International.

- ASTM Standard E466 - 15. Standard Practice for Conducting Force - Controlled Constant - Amplitude Axial Fatigue Tests of Metallic Materials.