The load - bearing capacity of aluminum cladding panels is a crucial factor that significantly impacts their performance and suitability for various construction projects. As a reputable supplier of aluminum cladding panels, I am well - versed in the intricacies of this topic and eager to share valuable insights.

Understanding Load - Bearing Capacity

Load - bearing capacity refers to the maximum amount of weight or force that a material can support without experiencing significant deformation, failure, or structural compromise. In the context of aluminum cladding panels, this encompasses both static and dynamic loads. Static loads include the weight of the panel itself, any insulation materials attached to it, and the weight of any additional elements such as signage or fixtures. Dynamic loads, on the other hand, are caused by external forces like wind, seismic activity, or the impact of falling objects.

Factors Affecting Load - Bearing Capacity

Panel Thickness

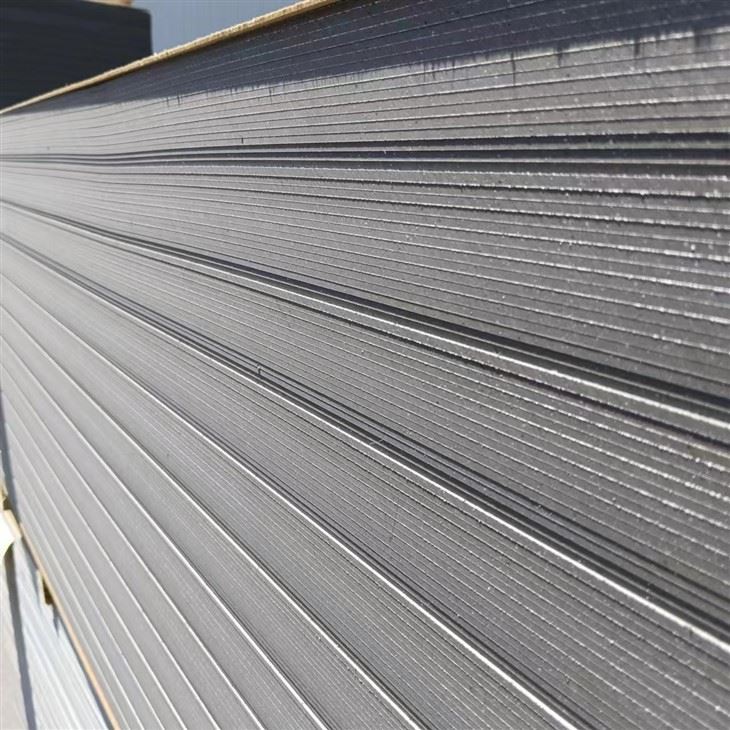

One of the most significant factors influencing the load - bearing capacity of aluminum cladding panels is their thickness. Generally, thicker panels can withstand greater loads. A thicker panel has more material to distribute the applied forces, reducing the stress on any single point. For instance, a 4 - millimeter thick aluminum cladding panel will typically have a higher load - bearing capacity than a 3 - millimeter thick one. This is because the additional material provides more resistance against bending and buckling under load.

Core Material

The core material of aluminum composite panels (ACPs) plays a vital role in determining their load - bearing capacity. Most ACPs have a polyethylene (PE) or mineral - filled core. PE cores are lightweight and offer good flexibility, but their load - bearing capacity may be limited compared to mineral - filled cores. Mineral - filled cores, which often contain materials like fire - retardant minerals, are denser and more rigid. They can better resist compression and shear forces, making them suitable for applications where higher load - bearing capacity is required. For example, in high - rise buildings exposed to strong winds, ACPs with mineral - filled cores are often preferred.

Panel Size

The size of the aluminum cladding panel also affects its load - bearing capacity. Larger panels are more prone to deflection under load compared to smaller ones. As the panel size increases, the distance between the supporting points becomes greater, and the panel has to span a larger area. This results in higher bending moments and increased stress on the panel. Therefore, when using large - sized panels, it is essential to ensure proper support and reinforcement to maintain their load - bearing capacity.

Surface Finish

The surface finish of aluminum cladding panels can indirectly affect their load - bearing capacity. For example, a panel with a PVDF (Polyvinylidene Fluoride) or PE coating, like the PVDF PE Coating ACM ACP Sheet Exterior Wall Aluminum Composite Panel, not only provides protection against environmental factors but can also enhance the panel's overall durability. A well - protected panel is less likely to experience corrosion or degradation over time, which could otherwise weaken the panel and reduce its load - bearing capacity.

Calculating Load - Bearing Capacity

Calculating the load - bearing capacity of aluminum cladding panels is a complex process that requires a thorough understanding of engineering principles. Structural engineers typically use mathematical models and software to analyze the panel's response to different loads. These calculations take into account factors such as the panel's material properties, dimensions, support conditions, and the magnitude and distribution of the applied loads.

In general, the load - bearing capacity of a panel is determined by its ability to resist bending, shear, and axial forces. For example, when a panel is subjected to a wind load, it experiences bending forces that cause it to deflect. The panel's ability to resist this deflection without exceeding its elastic limit is a measure of its load - bearing capacity.

Applications Based on Load - Bearing Capacity

Low - Rise Buildings

In low - rise buildings, such as single - family homes or small commercial structures, the load - bearing requirements for aluminum cladding panels are relatively low. These buildings are typically exposed to less severe wind and seismic loads. Therefore, thinner panels with a PE core, like the Cheap Exterior/interior Wall Cladding Panel Aluminium Composite Panel, can often meet the load - bearing needs. These panels are cost - effective and offer a good balance between aesthetics and performance.

High - Rise Buildings

High - rise buildings present more challenging load - bearing requirements. They are exposed to stronger winds and potential seismic activity. In such applications, thicker panels with mineral - filled cores are commonly used. Panels like the Alucobond Aluminum Composite Material are known for their high strength and load - bearing capacity, making them suitable for high - rise construction. These panels are designed to withstand the large lateral forces exerted by wind and seismic events without significant deformation.

Importance of Load - Bearing Capacity in Construction

Ensuring that aluminum cladding panels have adequate load - bearing capacity is essential for the safety and longevity of a building. If a panel fails to support the applied loads, it can lead to structural damage, such as cracks, delamination, or even collapse. This not only poses a risk to the occupants of the building but also results in costly repairs and downtime.

Moreover, meeting the load - bearing requirements is often a regulatory necessity. Building codes and standards specify the minimum load - bearing capacities for different types of construction projects. Failure to comply with these regulations can result in legal issues and delays in the construction process.

Testing and Certification

To guarantee the load - bearing capacity of aluminum cladding panels, rigorous testing and certification processes are in place. Manufacturers subject their panels to a series of tests, including static load tests, wind load tests, and seismic simulations. These tests are conducted in accordance with international standards such as ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization).

Certification from recognized testing agencies provides assurance to architects, contractors, and building owners that the panels meet the required load - bearing standards. When choosing aluminum cladding panels, it is crucial to select products that have been tested and certified to ensure their reliability and performance.

Conclusion

The load - bearing capacity of aluminum cladding panels is a multi - faceted concept that depends on various factors such as panel thickness, core material, size, and surface finish. Understanding these factors is essential for selecting the right panels for different construction applications. Whether it's a low - rise residential building or a high - rise commercial structure, choosing panels with adequate load - bearing capacity is crucial for ensuring the safety, durability, and compliance of the building.

If you are in the process of planning a construction project and need high - quality aluminum cladding panels with the appropriate load - bearing capacity, we are here to help. Our extensive range of products, including those mentioned in this article, is designed to meet diverse load - bearing requirements. Contact us today to discuss your project needs and explore the best solutions for your construction project.

References

- ASTM International. (20XX). Standards related to aluminum composite panels and load - bearing testing.

- ISO. (20XX). International standards for building materials and load - bearing capacity.

- Various research papers on the structural behavior of aluminum cladding panels.