As a seasoned supplier of ACP (Aluminum Composite Panel) sheets renowned for their fireproof properties, I've witnessed firsthand the transformative impact these panels have on modern construction and design. ACP sheets are a staple in contemporary architecture, offering a blend of aesthetics, durability, and practicality. One critical aspect that often comes under scrutiny is the fireproof effect of ACP sheets with different bonding methods. In this blog, we'll delve into the science behind these bonding techniques and their implications for fire safety.

Understanding ACP Sheets and Their Bonding Methods

ACP sheets typically consist of two aluminum sheets bonded to a core material, which can vary in composition. The bonding method is crucial as it determines the overall integrity and performance of the panel, especially in the face of fire. There are primarily two types of bonding methods used in the manufacturing of ACP sheets: chemical bonding and thermal bonding.

Chemical bonding involves the use of adhesives to join the aluminum sheets to the core. These adhesives are formulated to provide a strong and durable bond, ensuring the structural stability of the panel. The choice of adhesive can significantly impact the fireproof properties of the ACP sheet. High-quality adhesives with fire-resistant properties can enhance the panel's ability to withstand high temperatures and prevent the spread of fire.

On the other hand, thermal bonding uses heat to fuse the aluminum sheets to the core. This method is often preferred for its ability to create a more uniform and seamless bond, resulting in a stronger and more reliable panel. Thermal bonding can also improve the fireproof performance of ACP sheets by reducing the presence of flammable materials in the bonding layer.

Fireproof Effect of Chemically Bonded ACP Sheets

Chemically bonded ACP sheets have been widely used in the construction industry due to their versatility and cost-effectiveness. However, their fireproof performance can vary depending on the type of adhesive used. Some adhesives are more resistant to fire than others, and it's essential to choose a product that meets the required fire safety standards.

One of the key factors affecting the fireproof effect of chemically bonded ACP sheets is the ignition resistance of the adhesive. A high-quality adhesive with a high ignition temperature can prevent the panel from catching fire easily, providing valuable time for evacuation and firefighting. Additionally, the adhesive should be able to maintain its bond strength at high temperatures, ensuring the structural integrity of the panel during a fire.

Another important consideration is the smoke generation of the adhesive. In a fire situation, smoke can be just as dangerous as the flames themselves, as it can cause respiratory problems and reduce visibility. Adhesives that produce minimal smoke when exposed to fire can significantly improve the safety of the building and its occupants.

Fireproof Effect of Thermally Bonded ACP Sheets

Thermally bonded ACP sheets are known for their superior fireproof performance compared to chemically bonded panels. The thermal bonding process creates a more homogenous bond between the aluminum sheets and the core, reducing the risk of delamination and improving the panel's resistance to fire.

One of the main advantages of thermally bonded ACP sheets is their ability to withstand high temperatures without losing their structural integrity. The heat used in the bonding process can cause the core material to expand and form a protective layer, which can help to insulate the panel and prevent the spread of fire. Additionally, the absence of flammable adhesives in the bonding layer further enhances the panel's fireproof properties.

Thermally bonded ACP sheets also tend to produce less smoke and toxic gases during a fire compared to chemically bonded panels. This is because the bonding process eliminates the need for adhesives, which are often a major source of smoke and toxic emissions. As a result, thermally bonded ACP sheets can provide a safer environment for building occupants in the event of a fire.

Comparing the Fireproof Performance of Different Bonding Methods

When comparing the fireproof performance of chemically bonded and thermally bonded ACP sheets, it's important to consider the specific requirements of the project. While thermally bonded panels generally offer better fireproof properties, they may also be more expensive and less readily available than chemically bonded panels.

In some cases, chemically bonded ACP sheets may be a suitable option if the fire safety requirements are not as stringent. However, it's crucial to ensure that the adhesive used meets the relevant fire safety standards and has been tested for its fireproof performance. Additionally, proper installation and maintenance of the panels are essential to ensure their long-term fire safety.

On the other hand, thermally bonded ACP sheets are often recommended for applications where fire safety is a top priority, such as high-rise buildings, hospitals, and schools. These panels provide a higher level of protection against fire and can help to minimize the risk of property damage and loss of life.

Our Product Range and Fireproof Solutions

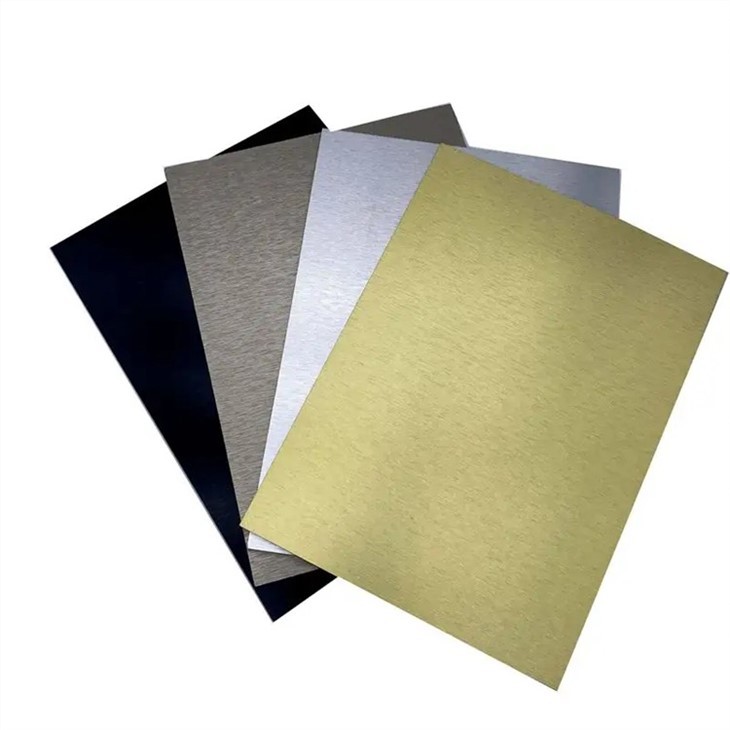

As a leading supplier of ACP sheets, we offer a wide range of products with different bonding methods to meet the diverse needs of our customers. Our New Design Brushed Alucobond Panel is a popular choice for its sleek and modern appearance, as well as its excellent fireproof properties. This panel is available in both chemically bonded and thermally bonded options, allowing you to choose the best solution for your project.

For those looking for a more cost-effective option, our 4*8ft Brushed Surface Aluminum Foil Composite Panel Display Signage ACP Sheet is a great choice. This panel is chemically bonded and offers a good balance between fireproof performance and affordability. It's ideal for use in a variety of applications, including signage, interior decoration, and cladding.

If you're in need of a high-performance ACP sheet with superior fireproof properties, our Alucobond 3/4mm Aluminum Plastic Panel ACM Sheet is the perfect solution. This panel is thermally bonded and provides excellent resistance to fire, smoke, and toxic gases. It's suitable for use in demanding applications where fire safety is of utmost importance.

Conclusion

The fireproof effect of ACP sheets with different bonding methods can vary significantly, and it's essential to choose the right product for your project. Chemically bonded ACP sheets offer a cost-effective option with satisfactory fireproof performance, while thermally bonded panels provide a higher level of protection against fire and are recommended for applications where fire safety is a top priority.

As a trusted supplier of ACP sheets, we are committed to providing our customers with high-quality products that meet the highest standards of fire safety. Whether you're looking for a stylish and modern panel for your building facade or a reliable solution for interior decoration, we have the expertise and products to meet your needs.

If you're interested in learning more about our ACP sheets and their fireproof properties, or if you have any questions or concerns, please don't hesitate to contact us. Our team of experts is always ready to assist you and provide you with the information and support you need to make an informed decision. We look forward to working with you on your next project and helping you create a safe and beautiful environment.

References

- ASTM International. (2023). Standard Test Methods for Fire Tests of Building Construction and Materials.

- ISO. (2023). Fire safety in buildings - Design, management and use.

- National Fire Protection Association. (2023). NFPA 101: Life Safety Code.