Hey there! As an aluminum composite ACM supplier, I often get asked about the cost of aluminum composite ACM. Well, let me tell you, it's not as straightforward as you might think. There are a bunch of factors that can influence the price, and I'm gonna break it down for you.

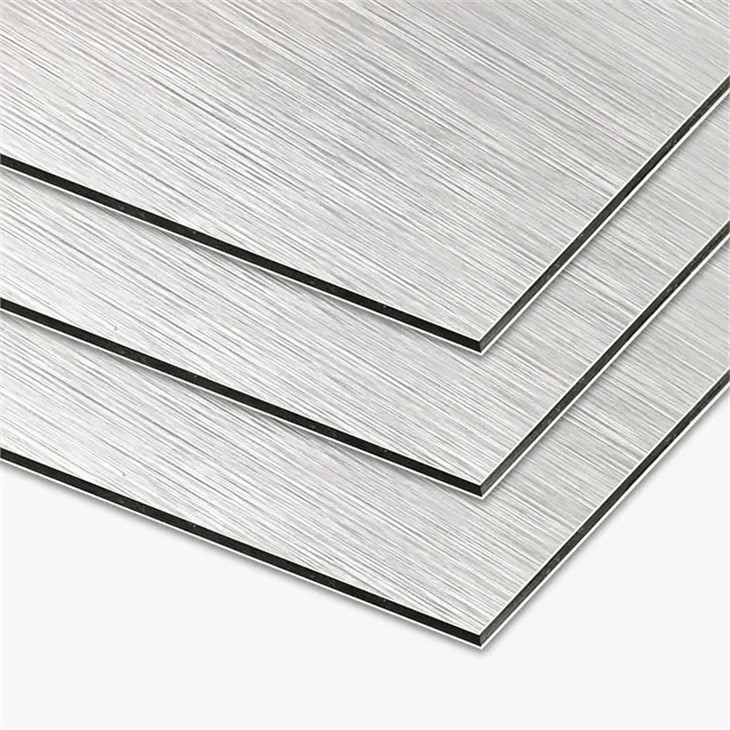

First off, let's talk about the materials. Aluminum composite panels are made up of two aluminum sheets bonded to a core material. The quality and type of these materials can have a big impact on the cost. For example, if you're using high - grade aluminum with a special finish, it's gonna cost more. And the core material also matters. Some cores are more fire - resistant, some are more lightweight, and these features can add to the price.

Take Alucobond 3/4mm Aluminum Plastic Panel ACM Sheet for instance. This is a well - known product in the market. The Alucobond brand is associated with high - quality materials and excellent manufacturing processes. The 3/4mm thickness is also a factor that affects the cost. Thicker panels generally cost more because they use more raw materials and require more processing.

Another important factor is the size of the panels. Larger panels usually cost more per square foot than smaller ones. This is because they need more aluminum and core material, and they're also more difficult to manufacture and transport. If you're planning a big project, you might be able to get a better deal on larger panels in bulk, but that's not always the case.

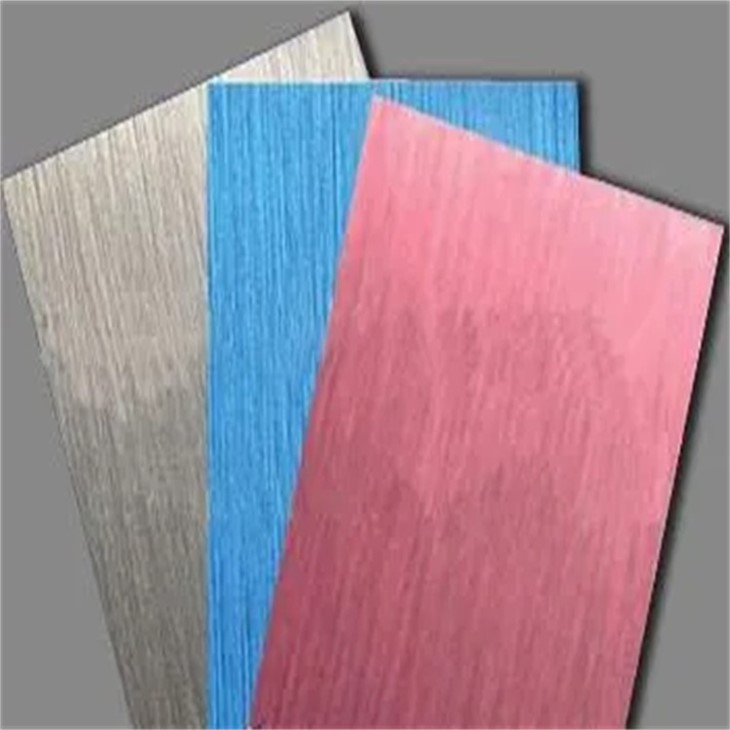

Surface finish is also a key element in determining the cost. A simple, standard finish will be cheaper compared to a fancy, custom - made finish. For example, Gold Brush ACP Cladding Sheet has a unique gold - brushed finish. This kind of finish requires additional processing steps, like special coating and brushing techniques, which drive up the cost.

Quantity is a no - brainer when it comes to pricing. Just like buying anything in bulk, if you order a large quantity of aluminum composite ACM, you're likely to get a lower price per unit. Most suppliers offer volume discounts to encourage customers to buy more. However, you need to make sure you have a proper storage space for the extra panels and that you'll actually use them.

Geographical location can also play a role in the cost. If you're located far away from the manufacturing facility, the shipping costs will be higher. Shipping large and heavy panels over long distances can add a significant amount to the overall price. Also, local market conditions, such as demand and competition, can affect the price you pay. In areas with high demand and limited competition, prices tend to be higher.

Customization is another factor that can jack up the cost. If you need panels in non - standard sizes, shapes, or colors, the supplier will have to do some extra work to meet your requirements. This might involve special cutting, shaping, and painting processes, all of which increase the production cost. For example, Broken Core Brushed Aluminum Cladding Panel might be a custom - designed product. The broken - core feature is not a standard one, so it will likely cost more than regular panels.

Now, let's talk about some ballpark figures. On average, basic aluminum composite ACM panels can cost anywhere from $3 to $10 per square foot. But if you're looking for high - end, custom - made panels with all the bells and whistles, the price can go up to $20 or more per square foot.

It's important to note that these prices are just estimates. The actual cost can vary widely depending on all the factors I've mentioned above. When you're getting quotes from suppliers, make sure you compare apples to apples. Ask about the specific materials, finishes, sizes, and quantities included in the price.

If you're in the market for aluminum composite ACM, I'd be more than happy to help you find the right product at the right price. Whether you're working on a small home improvement project or a large commercial building, I've got a wide range of options to suit your needs. Don't hesitate to reach out and start a conversation about your project. We can discuss the details, figure out what works best for you, and get you a competitive quote.

In conclusion, the cost of aluminum composite ACM is influenced by many factors, including materials, size, finish, quantity, location, and customization. By understanding these factors, you can make a more informed decision and get the best value for your money. So, if you're ready to take the next step in your project, let's talk!

References

- Industry reports on aluminum composite panel manufacturing and pricing

- Supplier price lists and product catalogs