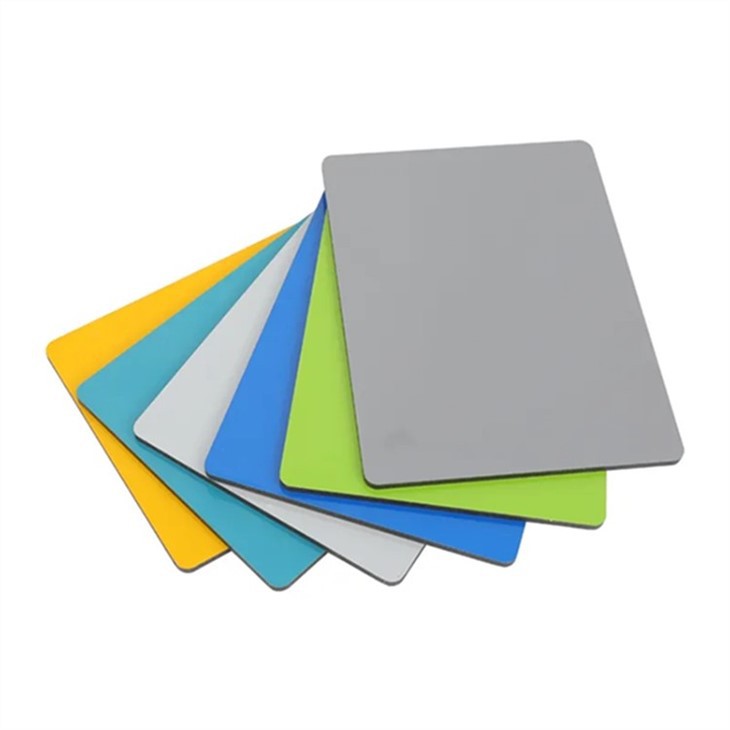

Hey there! As a supplier of ACP sheet cladding, I've seen firsthand the unique challenges that come with installing this stuff in complex building designs. ACP, or aluminum composite panel, is a popular choice for building exteriors because it's lightweight, durable, and comes in a variety of colors and finishes. But when you're dealing with a building that has an intricate design, things can get a bit tricky.

1. Design Complexity and Customization

First off, complex building designs often require a high level of customization. You can't just take a standard ACP sheet and slap it on a building with curves, angles, or irregular shapes. We've got to cut, bend, and shape the panels to fit the specific design requirements. For example, if a building has a circular facade, we need to create curved ACP sheets. This isn't as simple as it sounds. It requires special equipment and skilled technicians.

Moreover, the joints between the panels become a crucial factor. In a complex design, the joints need to be seamless and aesthetically pleasing. Any misalignment or visible gaps can ruin the overall look of the building. We often use Aluminum Composite Panel Supporting Service Silicone Glue to ensure a strong and tight bond between the panels. This glue not only provides structural support but also helps in achieving a smooth finish.

2. Structural Considerations

Another major challenge is the structural integrity of the building. ACP sheets are lightweight, but when you're covering a large and complex area, the weight can add up. The building's structure needs to be able to support the additional load. We need to work closely with architects and structural engineers to determine the best way to attach the ACP sheets.

Sometimes, we have to install additional support systems, like brackets or frames, to ensure that the panels are securely attached. This can be a time - consuming and costly process, especially in buildings with unique structural designs. For instance, in a building with a cantilevered section, we need to design a support system that can withstand the forces acting on the ACP cladding.

3. Weather and Environmental Factors

Weather can be a real pain when it comes to ACP sheet installation in complex buildings. Different regions have different weather conditions, and the ACP sheets need to be able to withstand them. In areas with high humidity, there's a risk of moisture getting trapped behind the panels, which can lead to corrosion and damage over time.

On the other hand, in regions with extreme temperatures, the expansion and contraction of the ACP sheets can cause problems. The panels need to be able to expand and contract without causing any damage to the joints or the overall structure. We often recommend using 4mm PVDF Fireproof Metal Composite Materials because they have better resistance to weather and environmental factors.

4. Fire Safety

Fire safety is a top priority in any building, and complex designs can make it even more challenging to ensure. ACP sheets need to meet certain fire safety standards. In some cases, we use fire - rated ACP sheets, like the B1 Fireproof White ACP Sheet for Kitchen. However, in complex buildings, the installation process needs to be carefully planned to prevent the spread of fire.

For example, the joints between the panels need to be sealed properly to prevent the passage of flames and smoke. We also need to ensure that there are no voids or cavities behind the panels that could act as a chimney for fire.

5. Installation Time and Labor

Installing ACP sheet cladding in complex building designs takes a lot of time and labor. The custom - cutting, shaping, and fitting of the panels require a high level of skill and precision. This means that we need to hire experienced installers, which can be expensive.

Moreover, the installation process is often slower in complex buildings because of the need for careful planning and measurement. Delays can occur due to unforeseen issues, like structural problems or weather conditions. This can lead to increased costs and longer project timelines.

6. Coordination with Other Trades

In a complex building project, there are usually multiple trades working simultaneously. We need to coordinate with other contractors, such as painters, electricians, and plumbers. For example, the ACP sheet installation needs to be done in a way that doesn't interfere with the electrical wiring or plumbing systems.

There can also be issues with access to the installation area. If other trades are working in the same area, it can be difficult to move the ACP sheets and equipment around. This requires good communication and planning to ensure that the project runs smoothly.

Wrapping Up and Reaching Out

Despite all these challenges, ACP sheet cladding can transform a complex building into a stunning architectural masterpiece. The key is to plan ahead, work with experienced professionals, and use high - quality materials.

If you're working on a complex building project and are considering ACP sheet cladding, I'd love to chat with you. We've got the expertise and the products to help you overcome these challenges and achieve the look you want for your building. Whether it's custom - cutting the panels, ensuring fire safety, or coordinating with other trades, we've got you covered. So, don't hesitate to reach out and start a conversation about your project.

References

- Building Construction Handbook: This handbook provides in - depth information on various construction materials and techniques, including ACP sheet installation.

- Fire Safety Standards for Building Materials: A comprehensive guide on the fire safety requirements for different building materials, which is crucial for ACP sheet cladding.

- Architectural Design Magazines: These magazines often feature case studies of complex building projects and the challenges faced during the construction process, including ACP sheet installation.