Hey there! As a supplier of B grade fireproof ACP (Aluminum Composite Panel), I'm super stoked to dive into the fire - prevention mechanisms of these awesome panels. Let's get right into it!

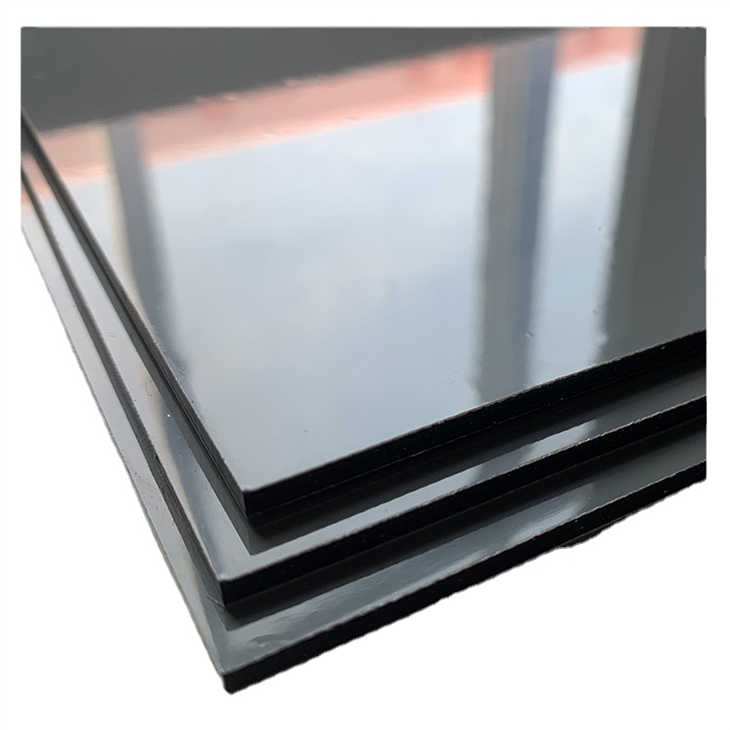

First off, what exactly is B grade fireproof ACP? Well, it's a type of building material that consists of two aluminum sheets bonded to a non - combustible or low - combustible core. The "B grade" classification means it has a certain level of fire resistance, which is crucial for ensuring the safety of buildings.

1. The Core Material

One of the key fire - prevention mechanisms lies in the core material of the B grade fireproof ACP. Most B grade fireproof ACPs use a core made of materials like mineral - filled polyethylene or fire - retardant polymers.

Mineral - filled polyethylene cores are great because they contain minerals that act as fire retardants. When exposed to fire, these minerals release water vapor. This water vapor cools down the surrounding area and dilutes the oxygen concentration near the fire. Without enough oxygen, the fire can't burn as vigorously, and it's less likely to spread. For example, the water vapor can reduce the temperature of the panel's surface, preventing the aluminum sheets from melting too quickly and maintaining the structural integrity of the panel.

Fire - retardant polymers, on the other hand, are designed to resist ignition and slow down the spread of fire. These polymers contain chemical additives that react when heated. They form a char layer on the surface of the core. This char layer acts as a barrier between the fire and the rest of the panel. It insulates the core from the heat, preventing the polymer from further decomposing and releasing flammable gases. This way, the fire is contained, and the panel can withstand the heat for a longer period.

2. The Aluminum Sheets

The outer aluminum sheets of the B grade fireproof ACP also play a significant role in fire prevention. Aluminum is a non - combustible material. It has a high melting point, which means it can withstand high temperatures without catching fire.

When a fire breaks out, the aluminum sheets act as a shield. They protect the core material from direct contact with the flames. The aluminum also conducts heat away from the fire source. This heat conduction helps to distribute the heat evenly across the panel, preventing any one area from getting too hot and potentially igniting the core.

Moreover, the aluminum sheets are usually treated with special coatings. These coatings can enhance the fire - resistant properties of the panel. For instance, some coatings can reflect heat, reducing the amount of heat absorbed by the panel. Others can form a protective layer when exposed to high temperatures, further preventing the spread of fire.

3. Adhesive Properties

The adhesive used to bond the aluminum sheets to the core is another important factor in the fire - prevention mechanisms of B grade fireproof ACP. High - quality adhesives are designed to maintain their integrity under high temperatures.

When a fire occurs, a good adhesive will not break down easily. It keeps the aluminum sheets firmly attached to the core, ensuring that the panel remains a single, cohesive unit. If the adhesive were to fail, the aluminum sheets could separate from the core, exposing the core to the fire and increasing the risk of the panel catching fire and spreading the flames.

4. Testing and Certification

To ensure the effectiveness of these fire - prevention mechanisms, B grade fireproof ACPs go through rigorous testing and certification processes. These tests simulate real - world fire scenarios to evaluate the panel's performance.

For example, the panels are tested for their ignition resistance, flame spread rate, and heat release rate. Only those panels that meet the specific standards for B grade fire resistance are certified. This certification gives architects, builders, and end - users confidence in the product's ability to prevent and contain fires.

Now, if you're in the market for high - quality B grade fireproof ACPs, you're in luck! We offer a wide range of products that are not only fire - resistant but also aesthetically pleasing. Check out our [ACP Sheet PE PVDF Manufacturer For Wall Cladding Alucobond](/high - gloss - aluminum - composite - panel/aluminum - composite - panel - acp - sheet - pe - pvdf.html). These panels are perfect for wall cladding and come in different finishes to suit your design needs.

If you're looking for a more modern and stylish option, our [High Gloss Composite Aluminium Cladding](/high - gloss - aluminum - composite - panel/high - gloss - composite - aluminium - cladding.html) is a great choice. It not only provides excellent fire protection but also adds a touch of elegance to any building.

And for those who need longer panels, our [Five Meters Length High Gloss Alucobond Panels](/high - gloss - aluminum - composite - panel/five - meters - length - high - gloss - alucobond.html) are just what you need. They offer the same great fire - prevention features along with the convenience of longer lengths.

Whether you're working on a small residential project or a large commercial building, our B grade fireproof ACPs are the perfect solution. If you're interested in learning more or placing an order, don't hesitate to reach out. We're here to help you with all your fireproof ACP needs.

References

- Fire Safety in Buildings: Principles and Practice. By John Galea and Claire Mulholland.

- Handbook of Fire Protection Engineering. By Arthur E. Cote.

- International Building Code (IBC) for fire - resistant building materials.