Hey there! As a supplier of PVDF aluminium cladding, I often get asked this question: Is PVDF aluminium cladding prone to discoloration in sunlight? Well, let's dive right into it and break it down.

First off, let's talk about what PVDF is. PVDF stands for Polyvinylidene Fluoride. It's a high - performance fluoropolymer coating that's commonly used on aluminium cladding. This coating is known for its excellent weather resistance, chemical resistance, and durability.

When it comes to sunlight, the sun emits a wide range of radiation, including ultraviolet (UV) rays. UV rays are the main culprit when it comes to the discoloration of many materials. Most traditional coatings can start to fade, chalk, or change color when exposed to prolonged UV radiation. But PVDF is different.

PVDF has a unique molecular structure. The carbon - fluorine bonds in PVDF are extremely strong. These bonds are able to withstand the energy of UV rays without breaking down easily. This means that PVDF aluminium cladding has a much higher resistance to UV radiation compared to other types of coatings.

In fact, numerous studies and real - world applications have shown that PVDF - coated aluminium cladding can maintain its color and appearance for a very long time, even under intense sunlight. For example, in regions with a lot of sunshine, like the deserts in the southwestern United States or the coastal areas of Australia, buildings clad with PVDF aluminium cladding have retained their original colors for decades.

However, it's important to note that no material is completely immune to the effects of sunlight. Over an extremely long period of time, say 20 - 30 years or more, there might be a very slight change in color. But this change is so minimal that it's hardly noticeable to the naked eye.

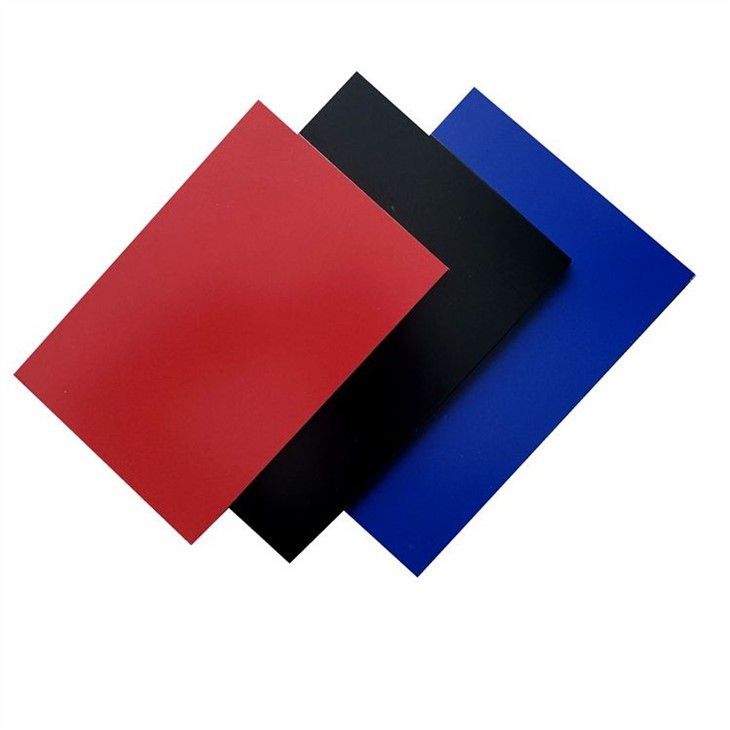

Now, let's compare PVDF with some other types of coatings. Take the PE Surface Coating ACP Aluminium Composite Panel for example. PE (Polyethylene) is a common surface coating for aluminium composite panels. While it's more affordable than PVDF, it doesn't have the same level of UV resistance. PE - coated panels are more likely to discolor in sunlight over time. You might start to see a fading or yellowing effect after just a few years of exposure.

Another popular option is the Light Grey 3mm ACP Sheet. If it's not coated with PVDF, the light grey color can be more susceptible to discoloration due to sunlight. The pigments in the coating can break down under UV rays, causing the color to change. But if it's a PVDF - coated light grey ACP sheet, you can expect it to keep its color for a much longer time.

And then there's the Export 3/4mm Wholesale Aluminum Sanwich Materials. When these materials are coated with PVDF, they offer better protection against sunlight - induced discoloration. This is crucial for wholesale buyers who want to ensure that their products look good and maintain their value over time.

So, if you're in the market for aluminium cladding that can stand up to the sun, PVDF is definitely a great choice. It gives you peace of mind knowing that your building's exterior will look great for years to come. Whether you're an architect designing a new commercial building, a contractor working on a residential project, or a property owner looking to renovate, PVDF aluminium cladding can meet your needs.

If you're interested in purchasing PVDF aluminium cladding, I'd love to talk to you. We have a wide range of colors, thicknesses, and finishes available. Just reach out, and we can discuss your specific requirements and how we can help you get the best - quality PVDF aluminium cladding for your project.

References

- "Fluoropolymer Coatings: Properties, Applications, and Market Trends" - A research report on the performance of fluoropolymer coatings like PVDF.

- "Long - Term Outdoor Exposure Testing of Building Materials" - A study that monitored the color stability of different building materials, including PVDF - coated aluminium, under sunlight.