In the construction and architectural industries, ACP (Aluminum Composite Panel) sheet cladding has gained significant popularity due to its versatility, aesthetic appeal, and cost - effectiveness. As a supplier of ACP sheet cladding, I am often asked about the environmental concerns associated with this product. In this blog post, I will delve into the various environmental aspects of ACP sheet cladding and provide a comprehensive analysis.

1. Raw Material Sourcing

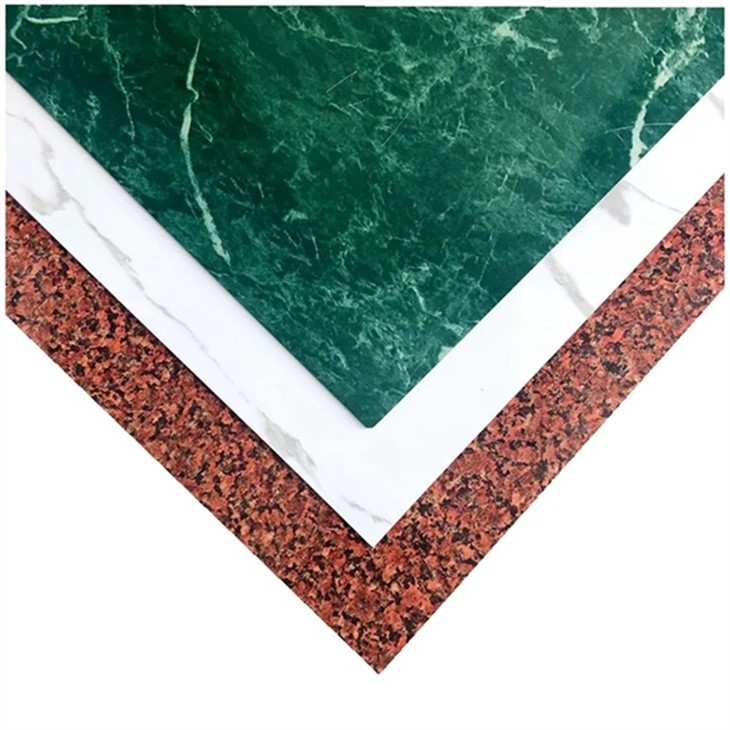

The primary raw materials for ACP sheet cladding are aluminum and the core material, which can be made of different substances such as polyethylene (PE), mineral - filled core, or fire - resistant materials.

Aluminum is a highly recyclable metal. According to the Aluminum Association, approximately 75% of all aluminum ever produced is still in use today. When sourcing aluminum for ACP production, responsible suppliers ensure that they use recycled aluminum whenever possible. Recycling aluminum requires only about 5% of the energy needed to produce new aluminum from bauxite ore. This significantly reduces the carbon footprint associated with the raw material extraction.

However, the core material can pose environmental challenges. Traditional polyethylene cores are derived from fossil fuels, which are non - renewable resources. The extraction and processing of fossil fuels contribute to greenhouse gas emissions, air pollution, and climate change. On the other hand, some manufacturers are now offering ACPs with mineral - filled or fire - resistant cores that are more environmentally friendly. These cores can be made from recycled materials or substances that have a lower environmental impact during production.

2. Manufacturing Process

The manufacturing process of ACP sheet cladding involves several steps, including bonding the aluminum sheets to the core material. Energy consumption is a major concern during this process. High - energy processes such as heating and pressing are required to ensure proper bonding of the layers.

To mitigate the environmental impact, many ACP manufacturers are investing in energy - efficient technologies. For example, some factories use advanced heating systems that reduce energy waste and optimize the production process. Additionally, manufacturers are implementing waste management strategies to reduce the amount of scrap material generated during production. Scrap aluminum can be recycled back into the production process, further reducing the demand for new raw materials.

3. Fire Safety and Environmental Concerns

Fire safety is a critical aspect of ACP sheet cladding. In recent years, there have been several high - profile building fires associated with ACPs, which has raised concerns about their fire - resistant properties. ACPs with polyethylene cores are highly flammable and can contribute to the rapid spread of fire in a building.

To address this issue, there are now fire - resistant ACP options available in the market. For example, the 920x1785mm Fireproof ACP ACM and B1 Fireproof White ACP Sheet for Kitchen are designed to meet strict fire safety standards. These fire - resistant ACPs use special core materials and coatings that inhibit the spread of fire. While these products enhance fire safety, it is important to note that the production of fire - resistant materials may involve the use of chemicals that can have environmental implications. Some fire - retardant chemicals can be toxic and may persist in the environment. Therefore, it is crucial for manufacturers to use environmentally friendly fire - retardant technologies.

4. Installation and Maintenance

During the installation of ACP sheet cladding, there is potential for environmental impacts. Construction waste, such as off - cuts of ACP sheets and packaging materials, can contribute to landfill waste. To reduce this impact, installers should be trained to minimize waste and recycle any usable materials.

Maintenance of ACP sheet cladding also has environmental implications. Regular cleaning and upkeep are required to ensure the longevity and aesthetic appeal of the cladding. However, the use of harsh cleaning chemicals can be harmful to the environment. Environmentally friendly cleaning products should be used instead. These products are biodegradable and do not contain toxic substances that can contaminate soil and water sources.

5. End - of - Life Disposal

At the end of its useful life, ACP sheet cladding needs to be disposed of properly. The aluminum component of the ACP can be recycled, which is a significant environmental benefit. Recycling aluminum helps conserve natural resources and reduces energy consumption.

However, the core material may pose challenges for disposal. Polyethylene cores are not easily biodegradable and can take hundreds of years to break down in landfills. In contrast, some mineral - filled or fire - resistant cores may be more easily recyclable or have a lower environmental impact during disposal.

6. Environmental Certifications and Standards

To ensure that ACP sheet cladding meets environmental standards, there are several certifications available. For example, the Leadership in Energy and Environmental Design (LEED) certification program in the United States encourages the use of sustainable building materials. ACPs that are made from recycled materials, have low - energy manufacturing processes, and are easily recyclable at the end of their life are more likely to meet LEED requirements.

Other international standards, such as the European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation, also play a role in ensuring the environmental safety of ACP products. These standards restrict the use of certain hazardous chemicals in the manufacturing process.

7. Our Company's Approach

As an ACP sheet cladding supplier, we are committed to minimizing the environmental impact of our products. We source aluminum from reliable suppliers who prioritize recycling. Our product range includes ACPs with environmentally friendly core materials, such as mineral - filled cores. We also offer Factory 1.22*2.44m Acp Sheet Panel that meet strict fire safety standards while using less harmful fire - retardant technologies.

We work closely with our manufacturing partners to implement energy - efficient production processes and waste management strategies. During the installation and maintenance phase, we provide our customers with guidelines on how to reduce environmental impacts, such as proper waste disposal and the use of eco - friendly cleaning products.

Conclusion

While there are some environmental concerns associated with ACP sheet cladding, the industry is making significant progress in addressing these issues. Through responsible raw material sourcing, energy - efficient manufacturing, and proper end - of - life disposal, the environmental impact of ACPs can be minimized.

If you are considering using ACP sheet cladding for your next project, I encourage you to contact us for more information. We can provide you with detailed product specifications, environmental data, and guidance on how to choose the most sustainable ACP option for your needs. Our team of experts is ready to assist you in making an informed decision that balances aesthetic appeal, functionality, and environmental responsibility.

References

- Aluminum Association. (n.d.). Aluminum Recycling. Retrieved from the official website of the Aluminum Association.

- Leadership in Energy and Environmental Design (LEED). (n.d.). Green Building Rating System. Retrieved from the official LEED website.

- European Union. (n.d.). REACH Regulation. Retrieved from the official European Union REACH website.