As a reputable supplier of aluminum composite materials (ACM), ensuring the safe transportation of our products is of utmost importance. Aluminum composite panels are widely used in various construction and decoration projects due to their lightweight, durability, and aesthetic appeal. However, improper handling and transportation can lead to damage, which not only affects the quality of the product but also incurs additional costs and delays for our customers. In this blog post, I will share some essential tips on how to transport aluminum composite ACM safely.

Pre - transportation Preparation

Inspection

Before loading the ACM panels for transportation, a thorough inspection is necessary. Check for any visible damage such as scratches, dents, or delamination on the panels. If any damaged panels are found, they should be separated and either repaired or replaced. This step helps to ensure that only high - quality products are sent to the customers and reduces the risk of disputes during transportation.

Packaging

Proper packaging is the first line of defense in protecting ACM panels during transit. The panels should be wrapped with protective films or papers to prevent scratches and surface damage. For larger shipments, the panels can be bundled together using straps or bands. Additionally, corner protectors can be added to the edges of the panels to prevent them from being chipped or bent during handling.

We offer a variety of ACM products, such as the Fireproof Building Materials Brushed Aluminum Composite Panel, which are carefully packaged to meet the highest transportation standards.

Loading Plan

Develop a detailed loading plan based on the quantity, size, and weight of the ACM panels. The panels should be loaded in a way that distributes the weight evenly across the transportation vehicle. This helps to maintain the stability of the vehicle and reduces the risk of the panels shifting during transit. For example, larger and heavier panels should be placed at the bottom, while smaller and lighter ones can be stacked on top.

Transportation Methods

Road Transportation

Road transportation is one of the most common methods for transporting ACM panels. When using trucks, it is important to choose a vehicle with a flatbed or a well - secured container. The panels should be loaded onto the truck in an orderly manner and secured with ropes or straps to prevent them from moving. The truck should also be equipped with a cover to protect the panels from weather elements such as rain, snow, and sunlight.

It is advisable to drive at a moderate speed and avoid sudden braking or acceleration, as these actions can cause the panels to shift and potentially get damaged. Additionally, regular checks should be made during the journey to ensure that the panels are still properly secured.

Sea Transportation

For international shipments or large - scale orders, sea transportation may be a more cost - effective option. When shipping ACM panels by sea, they are usually packed in shipping containers. The containers should be properly sealed to prevent water ingress and the panels should be arranged in a way that maximizes the use of space while ensuring their safety.

It is important to work with a reliable shipping company that has experience in transporting construction materials. The shipping company should be able to provide proper documentation and insurance coverage for the shipment.

Air Transportation

Air transportation is the fastest option for transporting ACM panels, especially for urgent orders or long - distance shipments. However, it is also the most expensive. When shipping by air, the panels need to be packed in a lightweight yet sturdy container. The packaging should be designed to meet the strict safety and security requirements of airlines.

Handling During Transportation

Lifting and Moving

When lifting and moving ACM panels, proper equipment such as forklifts or cranes should be used. The lifting points on the panels should be clearly marked, and the lifting equipment should be attached securely to these points. Workers should be trained on how to handle the panels correctly to avoid dropping or mishandling them.

Stacking

If the panels need to be stacked during transportation, it is important to stack them in a stable manner. The bottom layer of panels should be placed on a flat and even surface, and each subsequent layer should be aligned properly. The height of the stack should be limited to prevent the panels at the bottom from being crushed.

Unloading and Storage

Unloading

Upon arrival at the destination, the ACM panels should be unloaded carefully. The same safety procedures used during loading should be followed during unloading. Workers should check the panels for any damage that may have occurred during transportation. If any damage is found, it should be documented immediately and reported to the relevant parties.

Storage

After unloading, the ACM panels should be stored in a dry and well - ventilated area. They should be placed on a flat surface and protected from direct sunlight and moisture. If possible, the panels should be stored indoors to prevent them from being exposed to the elements.

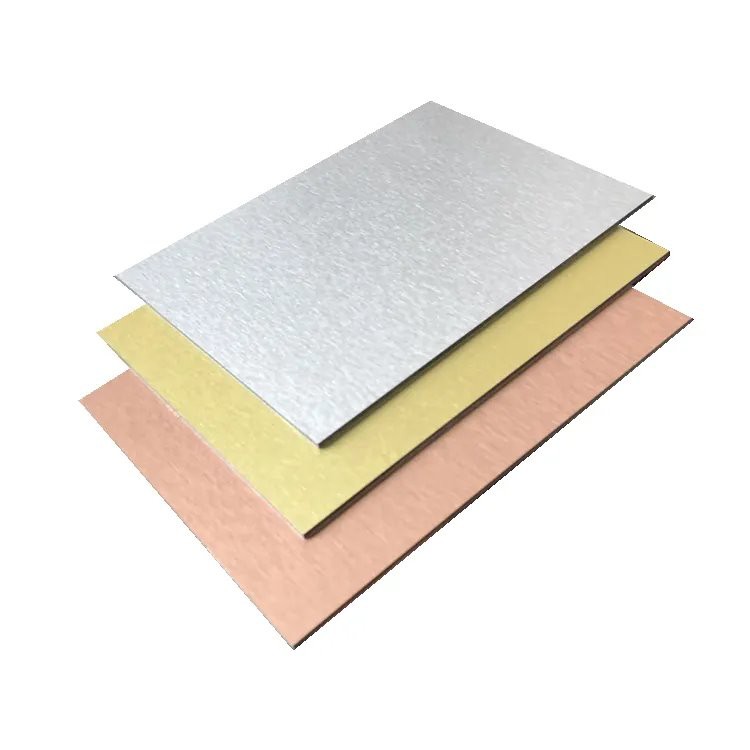

We also offer Gold Brush ACP Cladding Sheet, which require the same level of care during transportation and storage to maintain their high - quality finish.

Conclusion

Transporting aluminum composite ACM safely requires careful planning, proper packaging, and strict adherence to safety procedures. As a supplier, we are committed to ensuring that our products reach our customers in perfect condition. By following the tips outlined in this blog post, we can minimize the risk of damage during transportation and provide our customers with the best possible service.

If you are interested in our Top Quality ACP/ACM Aluminum Composite Panel Price or have any questions about transporting ACM panels, please feel free to contact us for further discussion and procurement negotiation. We look forward to working with you on your next project.

References

- "Aluminum Composite Panel Handbook", Industry Association of Construction Materials

- "Transportation Safety Guidelines for Building Materials", Department of Transportation