How to Connect ACP Panels Together?

As a well - established ACP panel supplier, I've witnessed firsthand the increasing popularity of Aluminum Composite Panels (ACP) in various construction and design projects. ACP panels are favored for their lightweight nature, durability, and aesthetic appeal. However, one of the key aspects that often concerns installers and project managers is how to connect these panels together properly. In this blog post, I'll share some comprehensive guidelines on this crucial topic.

Understanding the Basics of ACP Panels

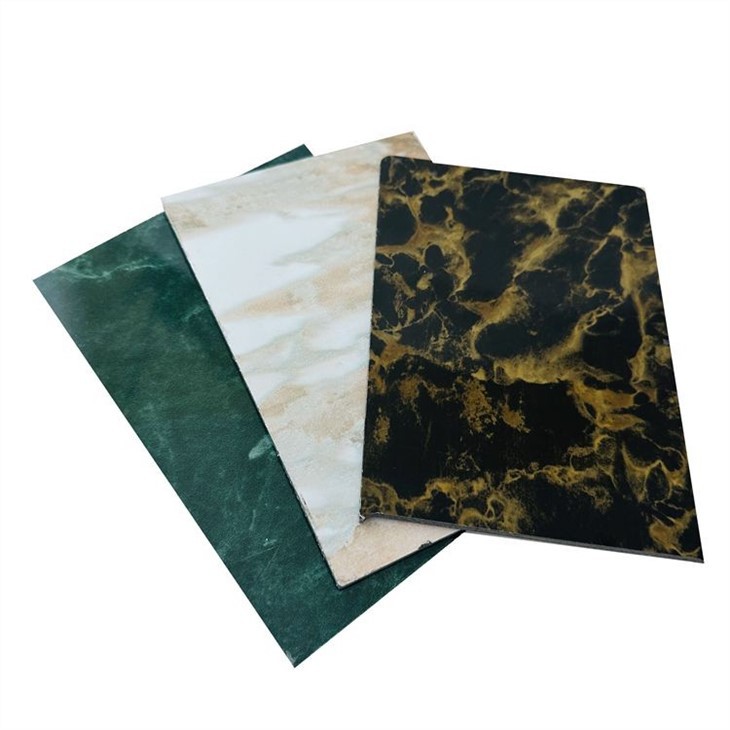

Before delving into the connection methods, it's essential to have a basic understanding of ACP panels. ACP panels typically consist of two thin aluminum sheets bonded to a non - aluminum core material, such as polyethylene or fire - retardant materials. The outer aluminum layers are often coated with finishes like PVDF (Polyvinylidene Fluoride) for enhanced weather resistance and color stability. You can explore our 4mm PVDF Coating ACP Sheet which offers excellent performance and visual appeal.

Tools and Materials Required

To connect ACP panels effectively, you'll need the following tools and materials:

- Measuring Tape: For accurate measurement of panel dimensions and alignment.

- Utility Knife: To cut the panels to the required size if necessary.

- Screw Gun or Drill: For installing screws or rivets.

- Sealant Gun: To apply sealant between the panels.

- Sealant: High - quality sealant suitable for outdoor use to prevent water infiltration.

- Screws or Rivets: Appropriate fasteners for the specific installation requirements.

Connection Methods

1. Mechanical Fastening

Mechanical fastening is one of the most common methods for connecting ACP panels. This involves using screws or rivets to secure the panels to the supporting structure.

- Screw Installation:

- First, mark the positions for the screws on the panel and the supporting frame. Make sure the marks are evenly spaced to ensure proper distribution of the load.

- Drill pilot holes in the panel and the frame to prevent the aluminum from cracking. The size of the pilot hole should be slightly smaller than the diameter of the screw.

- Insert the screws through the holes and tighten them using a screw gun. Be careful not to overtighten, as this can damage the panel.

- Rivet Installation:

- Rivets are another option for mechanical fastening. They are particularly useful in applications where a more permanent and vibration - resistant connection is required.

- Drill holes in the panels and the supporting structure. The holes should be of the appropriate size for the rivets.

- Insert the rivets into the holes and use a rivet gun to deform the rivet and create a secure connection.

2. Adhesive Bonding

Adhesive bonding can be used to connect ACP panels, especially in situations where a seamless appearance is desired.

- Surface Preparation:

- Clean the surfaces of the panels thoroughly to remove any dirt, grease, or debris. Use a suitable solvent to ensure a clean bonding surface.

- Roughen the surface slightly using sandpaper to improve the adhesion of the adhesive.

- Adhesive Application:

- Apply the adhesive evenly on one of the surfaces to be bonded. Make sure to follow the manufacturer's instructions regarding the amount and application method of the adhesive.

- Press the two panels together firmly and hold them in place for the recommended curing time. Use clamps if necessary to ensure a tight bond.

3. Edge - to - Edge Connection

Edge - to - edge connection is a common way to create a continuous surface with ACP panels.

- Joint Design:

- There are different types of joint designs, such as butt joints, lap joints, and mitred joints.

- Butt Joints: In a butt joint, the edges of the two panels are placed together flush. This type of joint requires careful alignment and can be sealed with a suitable sealant to prevent water penetration.

- Lap Joints: A lap joint involves overlapping the edges of the two panels. This provides additional strength and can also help in hiding any imperfections at the joint.

- Mitred Joints: Mitred joints are used to create a seamless corner. The edges of the panels are cut at an angle (usually 45 degrees) and then joined together. This type of joint requires precise cutting and alignment.

Considerations for Different Types of ACP Panels

There are various types of ACP panels available, such as Unbroken Core ACP Broken Core ACP Cladding ACP. The connection method may need to be adjusted based on the specific characteristics of the panel.

- Unbroken Core ACP: These panels are generally more rigid and may require more robust mechanical fastening methods to ensure a secure connection.

- Broken Core ACP: Broken core ACP panels are more flexible and may be more suitable for adhesive bonding or less - aggressive mechanical fastening methods.

Weatherproofing and Sealing

Regardless of the connection method used, proper weatherproofing and sealing are essential to prevent water infiltration and damage to the panels.

- Sealant Application:

- Apply a high - quality sealant along the joints between the panels. Make sure the sealant is compatible with the ACP panels and the environmental conditions.

- Use a sealant gun to apply the sealant evenly and smooth it out with a putty knife or a sealant finishing tool.

- Flashing Installation:

- In areas where water runoff is a concern, such as around windows and doors, install flashing to direct water away from the panels.

Quality Control and Inspection

After connecting the ACP panels, it's important to conduct a thorough quality control and inspection.

- Visual Inspection: Check for any visible gaps, misalignments, or damage to the panels. Make sure the joints are properly sealed and the fasteners are tightened correctly.

- Water Test: Conduct a water test to ensure that the panels are properly weatherproofed. Spray water on the panels and check for any signs of water leakage.

Conclusion

Connecting ACP panels together is a critical step in any ACP installation project. By following the proper connection methods, using the right tools and materials, and paying attention to details such as weatherproofing and quality control, you can ensure a successful and long - lasting installation.

If you're interested in purchasing high - quality ACP panels for your next project, feel free to explore our PVDF Aluminum Composite Panels ACP Sheet. Our team of experts is always ready to assist you with any questions you may have regarding panel selection, installation, or connection methods. Contact us today to start your procurement process and discuss your specific requirements.

References

- Aluminum Composite Panel Installation Guidelines, Industry Standard Publication

- Manufacturer's Technical Manuals for ACP Panels and Related Products