Temperature is a fundamental environmental factor that exerts a significant influence on various materials and structures, including ACP (Aluminum Composite Panel) wall cladding. As a leading ACP wall cladding supplier, we have witnessed firsthand the effects of temperature on the performance, durability, and aesthetics of our products. In this blog post, we will delve into the intricate relationship between temperature and ACP wall cladding, exploring how different temperature conditions can impact the material and offering insights on how to mitigate potential issues.

Thermal Expansion and Contraction

One of the most prominent effects of temperature on ACP wall cladding is thermal expansion and contraction. Like most materials, ACP panels expand when heated and contract when cooled. This phenomenon is governed by the coefficient of thermal expansion (CTE), which measures the rate at which a material expands or contracts in response to temperature changes.

The CTE of ACP panels typically ranges from 2.3 x 10^-5 to 2.5 x 10^-5 per °C, depending on the composition and manufacturing process of the panels. This means that for every 1°C change in temperature, an ACP panel will expand or contract by approximately 0.023 to 0.025 millimeters per meter of length.

In regions with significant temperature variations, such as deserts or areas with extreme seasonal changes, thermal expansion and contraction can cause ACP panels to warp, buckle, or develop cracks. These issues not only compromise the structural integrity of the cladding but also detract from its aesthetic appeal.

To mitigate the effects of thermal expansion and contraction, it is essential to allow for sufficient expansion joints when installing ACP wall cladding. Expansion joints provide space for the panels to expand and contract freely without causing damage to the cladding system. The size and spacing of expansion joints should be determined based on the local climate conditions, the size of the panels, and the type of installation.

Adhesive Bonding

Another critical aspect of ACP wall cladding that is affected by temperature is the adhesive bonding between the aluminum skins and the core material. The adhesive used to bond the layers of an ACP panel plays a crucial role in maintaining the structural integrity and performance of the cladding.

Temperature can have a significant impact on the adhesive bonding process. High temperatures can cause the adhesive to soften or degrade, reducing its bonding strength and potentially leading to delamination of the panels. On the other hand, low temperatures can slow down the curing process of the adhesive, resulting in incomplete bonding and reduced durability.

To ensure proper adhesive bonding, it is important to follow the manufacturer's recommendations regarding the temperature range for installation and curing. In general, the ideal temperature for installing ACP panels is between 10°C and 30°C. If the temperature falls outside this range, additional precautions may be necessary, such as preheating the panels or using a specialized adhesive designed for extreme temperatures.

Color Fading and Chalking

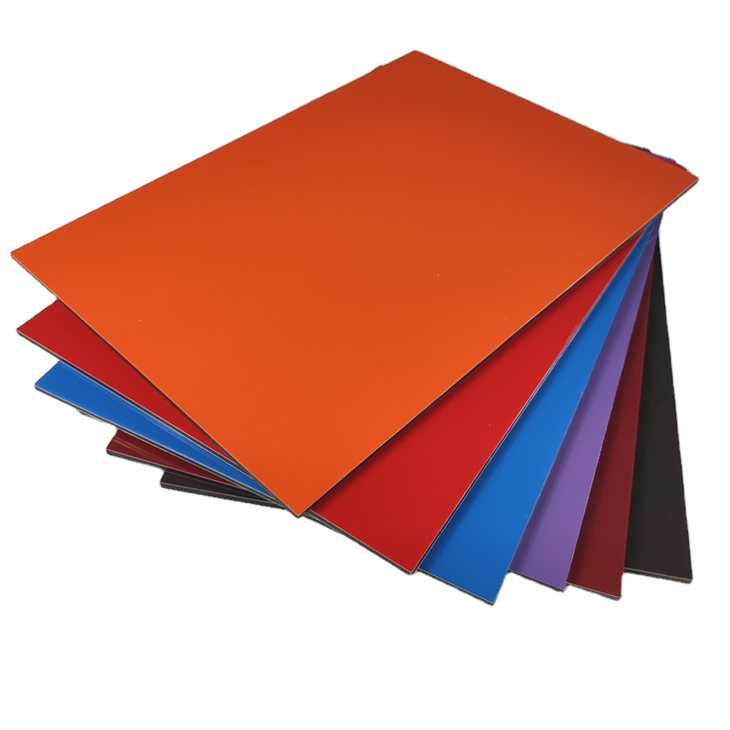

Temperature can also affect the color and appearance of ACP wall cladding. Prolonged exposure to high temperatures, especially in combination with sunlight and other environmental factors, can cause the surface finish of the panels to fade or chalk.

Color fading occurs when the pigments in the paint or coating of the ACP panel break down due to exposure to heat and ultraviolet (UV) radiation. Chalking, on the other hand, is the formation of a powdery residue on the surface of the panels, which is caused by the degradation of the binder in the paint or coating.

To minimize color fading and chalking, it is important to choose ACP panels with a high-quality paint or coating system that is specifically designed to resist UV radiation and heat. Additionally, regular maintenance and cleaning of the cladding can help to remove dirt, debris, and other contaminants that can accelerate the aging process.

Fire Resistance

Temperature can also have a significant impact on the fire resistance of ACP wall cladding. In the event of a fire, high temperatures can cause the core material of an ACP panel to melt or burn, releasing toxic gases and contributing to the spread of the fire.

To ensure the fire safety of ACP wall cladding, it is important to choose panels that are compliant with relevant fire safety standards and regulations. In many countries, ACP panels used for building external cladding are required to meet specific fire performance criteria, such as Class A or Class B fire ratings.

The fire resistance of ACP panels can be improved by using a fire-retardant core material and a fire-resistant paint or coating system. Additionally, proper installation and maintenance of the cladding can help to prevent the spread of fire and reduce the risk of structural damage.

Conclusion

In conclusion, temperature is a critical factor that can significantly affect the performance, durability, and aesthetics of ACP wall cladding. By understanding the effects of temperature on ACP panels and taking appropriate measures to mitigate these effects, it is possible to ensure the long-term performance and reliability of the cladding system.

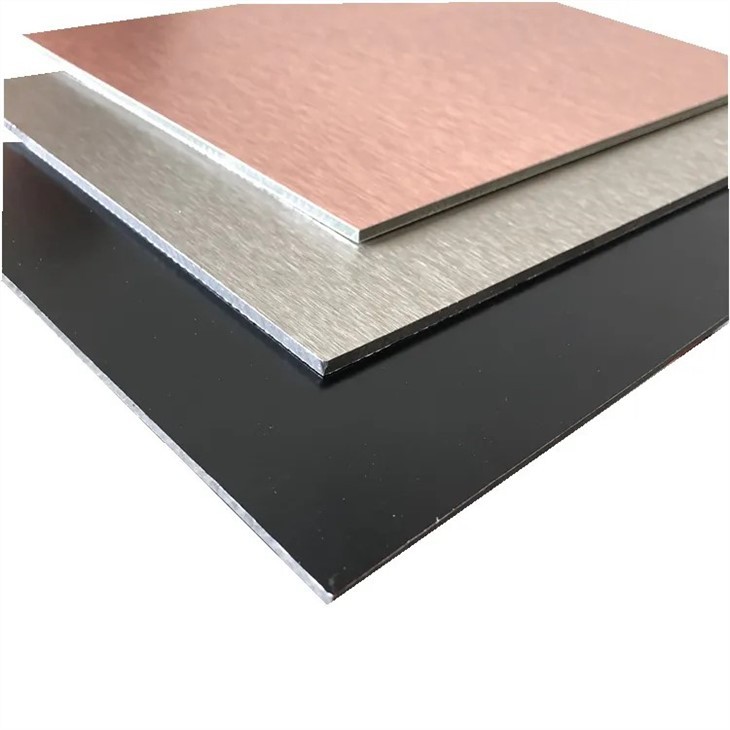

As a leading ACP wall cladding supplier, we are committed to providing our customers with high-quality products that are designed to withstand the challenges of various environmental conditions. Our Building Material ACP PE Coating Aluminum Composite Panel, Aluminum Composite Panel For Building External Cladding, and Composite Aluminum Panel Cladding are all engineered to meet the highest standards of quality and performance, ensuring that they provide long-lasting protection and aesthetic appeal for your building.

If you are considering using ACP wall cladding for your next project, we encourage you to contact us to discuss your specific requirements. Our team of experts will be happy to provide you with detailed information about our products, as well as guidance on installation, maintenance, and other aspects of ACP wall cladding. We look forward to working with you to create a beautiful and functional building envelope that meets your needs and exceeds your expectations.

References

- ASTM International. (2021). Standard Specification for Aluminum Composite Material (ACM) Panels for Exterior Wall Cladding. ASTM D6353-21.

- International Building Code (IBC). (2021). Chapter 26 - Aluminum.

- National Fire Protection Association (NFPA). (2021). NFPA 285 - Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Nonload - Bearing Wall Assemblies Containing Combustible Components.