PVDF (Polyvinylidene Fluoride) aluminium cladding is a popular choice for building exteriors due to its durability, aesthetic appeal, and weather resistance. In areas with heavy snowfall, the performance of cladding materials is crucial to ensure the long - term integrity and functionality of buildings. As a PVDF aluminium cladding supplier, I will explore how PVDF aluminium cladding performs in such challenging environments.

Structural Integrity under Snow Load

One of the primary concerns in areas with heavy snowfall is the ability of the cladding to withstand the weight of accumulated snow. PVDF aluminium cladding typically consists of a core material sandwiched between two aluminium sheets coated with PVDF. The aluminium sheets provide strength and rigidity, while the PVDF coating offers protection against corrosion and weathering.

The structural design of PVDF aluminium cladding allows it to distribute the snow load evenly across the surface. The cladding panels are usually installed in a way that they are securely attached to the building structure, ensuring that they can resist the downward force exerted by the snow. For example, in a multi - story building in a snowy region, the PVDF aluminium cladding panels are fixed to the frame using appropriate fasteners, which prevent the panels from sagging or detaching under the weight of the snow.

According to engineering standards, the snow load capacity of building cladding is calculated based on the local snowfall data, including the average snow depth, density, and frequency of heavy snow events. PVDF aluminium cladding can be designed and engineered to meet these specific requirements. For instance, in areas with extremely heavy snowfall, thicker aluminium sheets or reinforced core materials can be used to enhance the load - bearing capacity of the cladding.

Resistance to Snow - Related Corrosion

Snow can bring with it various environmental factors that may cause corrosion to building materials. In areas with heavy snowfall, de - icing salts are often used on roads and sidewalks, and these salts can be carried by the wind and deposited on the building facade. PVDF coating on aluminium cladding provides excellent resistance to corrosion caused by these salts.

The PVDF coating forms a protective barrier on the surface of the aluminium sheets, preventing the penetration of moisture and corrosive substances. This is particularly important in coastal regions where the snow may also contain saltwater. Even when the cladding is exposed to a combination of snow, ice, and salt for an extended period, the PVDF coating maintains its integrity, ensuring that the aluminium cladding remains in good condition.

A study conducted by a research institution on the long - term performance of building cladding materials in snowy and coastal areas found that PVDF aluminium cladding showed significantly less corrosion compared to other types of cladding materials. After several years of exposure to snow, ice, and salt, the PVDF - coated aluminium panels retained their original appearance and structural properties, while uncoated or poorly coated materials showed signs of rust and degradation.

Thermal Performance in Cold and Snowy Conditions

In cold and snowy areas, the thermal performance of building cladding is essential for energy efficiency. PVDF aluminium cladding can contribute to the building's thermal insulation. The air gap between the cladding panels and the building wall acts as an insulating layer, reducing heat transfer between the interior and the exterior of the building.

During the winter, the cladding helps to keep the heat inside the building, reducing the energy consumption for heating. In addition, the PVDF coating has low emissivity, which means it reflects a significant amount of infrared radiation back into the building. This property further enhances the thermal insulation effect of the cladding.

For example, in a residential building in a snowy area, the use of PVDF aluminium cladding can reduce the heating bills by up to 15% compared to a building with traditional cladding materials. The cladding also helps to maintain a more stable indoor temperature, providing a comfortable living environment for the occupants.

Aesthetic and Durability in Snowy Scenery

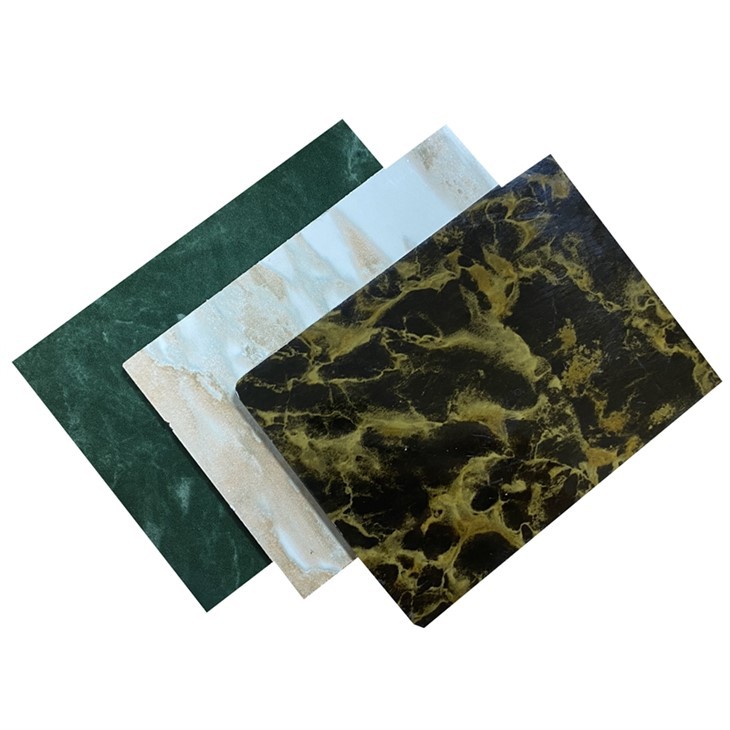

PVDF aluminium cladding offers a wide range of colors and finishes, which can enhance the aesthetic appeal of buildings in snowy landscapes. The bright and vivid colors of the PVDF coating stand out against the white snow, creating a visually striking appearance. Whether it is a modern commercial building or a traditional residential house, PVDF aluminium cladding can be customized to match the architectural style and design concept.

Moreover, the durability of PVDF aluminium cladding ensures that the building maintains its aesthetic value over time. The PVDF coating is highly resistant to fading, chalking, and cracking, even after years of exposure to harsh winter conditions. This means that the building will continue to look attractive and well - maintained, regardless of the amount of snowfall.

Comparison with Other Cladding Materials

When compared to other cladding materials such as Aluminium Composite Panel Exterior Cladding Wall Clading, PE Aluminium Composite Panel ACP Sheet Cladding Wall Cladding, and Normal Core And Unbreakable Aluminum Composite Panel Wall Cladding Sheet, PVDF aluminium cladding has several advantages in areas with heavy snowfall.

PE aluminium composite panels may have a lower cost, but they may not offer the same level of corrosion resistance and durability as PVDF aluminium cladding. The PE core material may be more susceptible to moisture absorption, which can lead to swelling and degradation over time, especially in snowy and wet conditions.

On the other hand, normal core and unbreakable aluminum composite panels may have different performance characteristics. While they may be strong and unbreakable, their thermal performance and aesthetic options may be limited compared to PVDF aluminium cladding. PVDF aluminium cladding combines the strength of aluminium with the superior protection and aesthetic qualities of the PVDF coating, making it a more suitable choice for areas with heavy snowfall.

Contact for Procurement

If you are looking for high - quality PVDF aluminium cladding for your building project in an area with heavy snowfall, we are here to assist you. Our team of experts can provide you with detailed information about the product specifications, performance, and installation requirements. We can also offer customized solutions based on your specific needs and the local environmental conditions. Whether you are an architect, builder, or property owner, we are committed to providing you with the best products and services. Contact us today to start the procurement process and ensure that your building is well - protected and aesthetically pleasing in snowy conditions.

References

- ASTM International. (20XX). Standard test methods for evaluating the performance of building cladding materials.

- National Snow and Ice Data Center. (20XX). Snowfall data and analysis for different regions.

- Research Institute on Building Materials. (20XX). Long - term performance study of building cladding materials in cold and snowy areas.