Linyi Alux Building Material Co.,Ltd

Linyi Alux Building Material Co.,Ltd. is a 25 years'factory founded in 1998, which mainly produces aluminum composite panel with 8 ACP production lines. We created our trading company Linyi Alux Import and Export Co.,Ltd. in 2018, exported to the whole Asian, African countries, Middle east, and the North and South America.

Why Choose Us

Rich Experience

Providing technical support, troubleshooting, and maintenance services.

One-stop Solution

Support to customers to ensure a smooth transaction.

Production Market

Exported to the whole Asian, African countries ,Middle east, and the North and South America.

Our Service

Our service runs throughout the whole production process from the pre-sales, product design, production and after-sales.

-

4mm Alucobond ACP Cladding Panels

Export 3/4mm Wholesale ACP Sheet Add to Inquiry -

Alucobond For Exterior Usage

Export 3/4mm Wholesale Aluminum Sanwich Materials Add to Inquiry -

Export 3/4mm Wholesale Aluminum Sanwich Materials

Export 3/4mm Wholesale Aluminum Sanwich Materials Add to Inquiry -

Factory Wholesale Aluminum Composite Panel

Good weather resistance, high strength, and easy maintenance. 2. Convenient construction and short Add to Inquiry -

4mm Outdoor ACP Manufacturer

Aluminum plastic composite board is composed of multiple layers of materials, with high-purity Add to Inquiry -

Alucobond Aluminum Composite Material

Fireproof aluminum composite panel is a commonly used building material in construction and Add to Inquiry -

Composite Aluminum Panel Cladding Grooving

Application scope:. 1) Renovation. 2) Outdoor wall. 3) Interior walls. 4) Shop door decorations. 5) Add to Inquiry -

Composite Aluminum Panel Cladding

Interior ACP SPEC:Aluminum thickness:0.03mm,0.06mm,0.09mm,0.1mm,0.12mm,0.15mm,0.18mm,0.21mm Add to Inquiry -

3mm Pe Coating Indoor Decoration Aluminium Composite Pane...

Warranty:More than 5 years. After-sale Service:Online technical support. Size:1220*2440mm. Add to Inquiry -

New Protective Film For Aluminum Composite Panels

Aluminum Composite Panels also knows as ACP ACM. Add to Inquiry -

LDPE Composite Aluminum Panel As Cabinets

LDPE Composite Aluminum Panel As Cabinets Add to Inquiry -

Aluminium Composite Panel For Interior/Exterior Decoration

Aluminum Composite Panels also knows as ACP ACM. Add to Inquiry

As previously mentioned, there have been some limitations for applying the PE aluminum composite panel in some countries. The reason for banning PE in countries relates to their fire behavior. There has been some evidence that the PE cores can spread the fire quickly compared to fire-retardant materials, which stops spreading fire mainly if ACP is used for cladding or facade. Therefore, PE aluminum composite panel usage is more limited and mostly applies to indoor applications. Here are some of the indoor usages of aluminum composite panels.

Wall covering: The wall covering of aluminum composite sheets for the interior part of a project is the same as cladding for exterior use. However, the risk of fire is significantly reduced in the internal part of the buildings. That's why PE panel will not cause any trouble when used for interior applications.

Internal decoration: Wall covering can be considered one part of interior decoration; however, more details can be applied for internal decoration. For instance, kitchen and room decoration are typical by using ACP Panels.

False ceilings: The ACP features and characteristics have made it possible to use false ceiling by applying aluminum composite sheets. Some features, such as exceptional insulation properties required for false ceilings, are simply found in ACM panels.

Partitions: Mostly used in offices, partitions are applied in places where heat and sound insulation is necessary. Aluminum composite panels can provide exceptional insulation features. Moreover, the durability of ACM sheets can also be handy in these circumstances.

PE Aluminum Composite Panel; Are they better than FR ACM Panel?

The construction materials have significantly evolved for the past few years that choosing the correct one seems rather a challenging task. Besides traditional materials such as fire bricks and clay blocks, modern construction elements have been common recently. Moving away from conventional materials was not easy; however, modern elements' high-qualities have made the job easier. One of these new construction materials is aluminum composite panel. Even though they were invented in the 1960s, their popularity has increased in the current decade. Various elements can decide whether an ACP Panel is suitable and ideal for your application or not, one of them being PE aluminum composite panel. For more information about these materials, you can visit aluminum sandwich panel.

PE aluminum composite panel stands for any aluminum composite sheets that include polyethylene in its structure. Though there has been some criticism for the usage of PE in aluminum composite panels, manufacturers and providers still use this material in their products depending on the user application. In other words, your usage defines whether using PE aluminum composite panel is the correct thing or not. First things first, we need to know more about polyethylene.

What is polyethylene?

To put it in simple words, polyethylene is related to the typical plastic materials we use every day. However, industry usage is a bit different. Polyethylene is considered a reliable, lightweight, and robust thermoplastic element with a crystalline structure. Their use is so much that the production rate can not be estimated though it is believed that more than ten tons of plastic are produced annually.

Polyethylene has various applications in the industry. Some of the most well-known polyethylene applications are films, tubes, plastic parts, laminates, and aluminum composite panels. PE aluminum composite panel is designed to withstand harsh, severe, cold, or hot conditions.

PE Aluminum Composite Panel Benefits

The fact that many buildings and projects today use ACP as their primary material shows how trustworthy aluminum composite panel is. It's not even that. If you read the advantages and qualities of PE aluminum composite panel, you can notice why they have been so popular. For more information, you can visit ACM sheets. Here are some of the advantages and features of PE aluminum composite panel:

PE is light in weight

We can undoubtedly say that PE is used in aluminum composite panel core due to its lightweight. The lightweight of aluminum composite sheets has allowed clients to use them in cladding, wall partitions, rooftops, train stations, false ceilings, and even the transportation and aircraft industry. Furthermore, PE usage in ACM panels has resulted in a more cost-effective material, which is essential when building a custom house.

Durability

Though at first, you might assume that PE is not durable, you need to reconsider. Aluminum composite panels are one of the most durable and rigid materials available worldwide. Even in cold climates such as Canada, ACM panels with the PE core can withstand winter's cold days.

Flexibility

Lightweight, durable, and flexible are the words that are hard to exist in construction material. Still, with the correct usage of structural properties, ACM panel has been made possible.

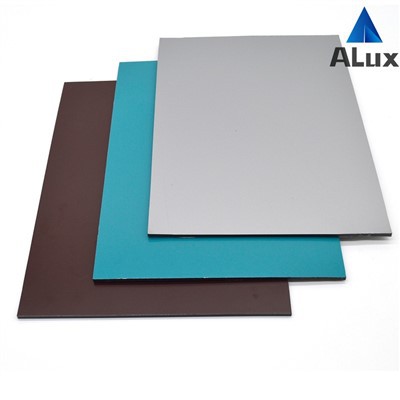

Color choice

Though color choice, like the previous features, is not explicitly related to the PE materials. Aluminum composite panels can offer various color choices to increase the charisma of your construction, project, or decoration elements. For instance, the PE aluminum composite panel is available in both solid and corporate colors. The solid colors are suitable for custom house builders, whereas the corporate colors are ideal for advertisement and business people. Furthermore, the customization of the panels is also possible. Various finishes such as mirror, marble, wooden, and more textures can be purchased for the PE aluminum composite panel.

Final thoughts: PE Aluminum Composite Panel; Does it worth it?

The PE aluminum composite panel ban is not the same in different countries. Some regulations don't allow the use of PE in the buildings or cladding materials in some states. That's not always the case, though. Some other countries allow PE ACM panel only for one or two-floor buildings. For more than two-floor buildings, it is advisable to implement FR cores.

The price comparison between PE and FR cores clearly shows that PE cores are most budget-friendly. Therefore, when purchasing a suitable material for your construction project, always contact your supplier for more information. Our experts are also available for any questions you have. Furthermore, you can visit aluminum composite material for an in-depth review of ACM panels.

Amazing Advantages of Using Aluminum Composite Panels in Buildings

Aluminum composite panels (ACP) refer to thin panels of two coiled aluminum sheets without an aluminum core. They are made with polyethylene and a fire-resistant filler. ACPs are popular for their fine finishes and lightweight properties. In this piece, we list some amazing properties of aluminum composite panels that make them popular for building projects.

Lightweight

When it comes to coating or finishing surfaces, aluminum composite panels are preferred because they are lightweight. Aluminum composite panels are approximately 66% lighter than materials like steel and other metals, weighing as low as 4.6 kg per square meter.

Available in Different Shapes, Sizes, and Colours

Aluminum composite panels come in a variety of shapes, sizes, and colours. They can be used to coat different types of systems as well as for creative projects with a wide array of colours available. They can also be cut to fit specific sizes and shapes if the need arises.

Cost-Effective

Aluminum composite panels are cost-effective building solutions because they are easy to use and cost less to maintain than other metal options. They also cost less to install in terms of labour and purchasing materials.

Anti-Corrosion

Aluminum composite panels are pretreated with a protective coating that provides additional protection from corrosion. However, the aluminum panels also release a thin layer of aluminum oxide that keeps the panel from corroding when exposed to air. This makes it easy to maintain the external appearance of the panels.

Low Cost of Maintenance

Aluminum composite panels require very little to no maintenance compared to other finishes like steel and wood which require a lot of maintenance and can be quite expensive to maintain. Aluminum composite panels require cleaning once a year; however, it's best to contact professionals to handle the cleaning.

Highly Functional

Aluminum composite panels are highly functional in that they are available in different shapes, sizes, colours, and even types and they can be used for their thermal properties, insulation of sound, and wind. They are also easy to clean and can be used to reduce the cost of energy. Aluminum composite panels can also be recycled.

Safe to Use

Aluminum composite panels are built with fire-resistant materials and are even earthquake-resistant making them a safe option for building adventures. There are reduced risks of fire outbreaks as well as lower chances of damaging structures due to earthquakes and small disasters.

Eco-Friendly

Aluminum composite panels are environmentally friendly because they can be recycled to create other products. Also, they are made from recycled materials like aluminum, minerals, and a few other polymers. Aluminum composite panels can retain all properties during their making and design stage.

Durability

Aluminum composite panels are durable due to the non-corrosive characteristics that keep them from getting damaged easily. Also, their ability to be combined with other products makes them last longer; thereby, making them a good option for building projects.

Good Design Options

Another amazing property of aluminum composite panels is that there are numerous design options to choose from depending on the type of project or the type of finishing required. They are available in different colours and textures, which makes them very versatile for building projects.

There are several methods for installing aluminum composite panels in buildings and they include.

Welding

Hot air welding with the aid of a solder is the most common method of installing aluminum composite panels. This method is preferred for the strength of the connection created and the

joint can last a long time without repairs.

Screwing

Aluminum composite panels can be attached by screws. This method is also durable and can be used for both interior and exterior surfaces. Gaskets are used for external screw installations.

Gluing

Another method of installing aluminum composite panels is with the use of metal glues or other high-tension adhesives. This is another long-lasting method of installing aluminum composite panels; however, this method is not advised for use in areas that are exposed to moisture.

PE Core vs FR Core - Which Is Right For Your Project

With hundreds of materials and applications available to the architectural industry, it is important to know all the facts before dressing your building. In this post, we will examine the differences between a PE Core and FR Core that is found in the Aluminium Composite Panel application.

Polyethylene Core Panel (PE)

Firstly, an aluminium composite panel with polyethylene core (PE) is a panel that has a thermoplastic polyethylene material at its core surrounded by two thin sheets of aluminium. PE core composite panels offer benefits like rigidity, light weight, ease of fabrication and adaptability.

Fire Retardant Core Panel (FR)

Contradistinction, an aluminium composite panel with a fire retardant core (FR) is a panel that has a mineral filled thermoplastic core bounded by two thin sheets of aluminium. FR core composite panels also offer similar benefits to PE core composite panels. The exception being that FR core panels offer compliance with many fire codes worldwide.

It's important to understand that no aluminium composite panel is fire-proof, only fire code compliant. As any other metal, all aluminium will melt at some point; however, the key factor between these two products is that the FR Core is a non-fire rated panel that has been deemed acceptable for a fire-rated construction assembly.

The Best Choice For You

Given tight budgets, it is important to keep the following items in mind when determining if FR core is warranted for your project.

Availability

FR Core material is not typically held in stock at a manufacturer's facility. Therefore, PE Core material is more likely to be available with custom colours, standard colours, and finish selections.

Minimum Order Quantities

FR Core is typically produced once every few weeks depending on the manufacturer. Some manufacturers may even wait until a minimum quantity is ordered before agreeing to production runs – this minimum quantity refers strictly to the amount of FR Core material; colour and finish do not weigh into the decision. For example, a manufacturer may set a minimum order quantity of 30 sheets or a certain square footage to process the material; therefore, a project requiring only 6 sheets of material would need to be priced as if you were buying 30 sheets.

Certificate

Our Factory

We created our trading company Linyi Alux Import and Export Co.,Ltd. in 2018 , exported to the whole Asian, African countries ,Middle east, and the North and South America. With an annual export volume of 1.5 million US dollars, we are the largest Aluminum Composite Panel exporter in northern China.

FAQ

We're professional pe aluminum composite panel manufacturers and suppliers in China, specialized in providing high quality customized service. If you're going to buy discount pe aluminum composite panel in stock, welcome to get pricelist and free sample from our factory. Good service and low price are available.

Standard Size PE ACP for Outdoor Wall Cladding, wall cladding, aluminium composite panel cladding