As a seasoned supplier of fire retardant Aluminum Composite Panels (ACP), I've witnessed firsthand the growing demand for building materials that combine safety, aesthetics, and durability. One crucial aspect that often comes under scrutiny is the impact resistance properties of fire retardant ACP. In this blog post, I'll delve into the science behind these properties, explore their real - world implications, and highlight why our products stand out in the market.

Understanding Impact Resistance

Impact resistance refers to a material's ability to withstand sudden forces or blows without suffering significant damage. For fire retardant ACP, this property is of utmost importance, especially in applications where the panels may be exposed to accidental impacts, such as in commercial buildings, transportation hubs, or industrial facilities.

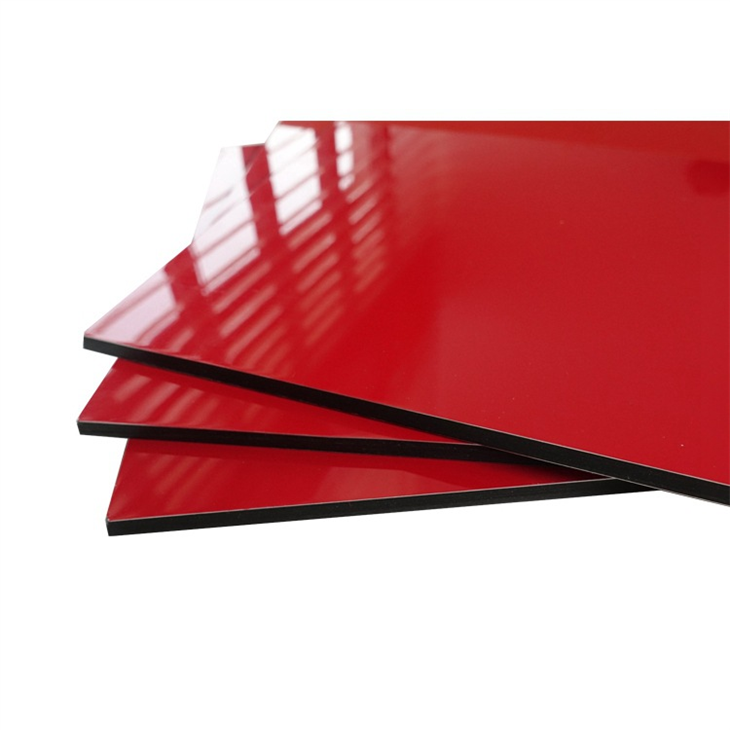

The impact resistance of fire retardant ACP is determined by several factors, including the composition of the panel, the thickness of the aluminum skins, and the nature of the core material. Our fire retardant ACP typically consists of two aluminum sheets bonded to a non - combustible core. The aluminum skins provide strength and stiffness, while the core material contributes to the panel's overall stability and fire - resistant properties.

The Role of Aluminum Skins

The thickness and quality of the aluminum skins play a vital role in the impact resistance of fire retardant ACP. Thicker aluminum skins generally offer better impact resistance as they can absorb and distribute the energy of an impact more effectively. Our ACP products use high - grade aluminum alloys with carefully selected thicknesses to ensure optimal performance.

For instance, in our Glossy Matt Pure Color Aluminum Composite Board Wholesale, the aluminum skins are engineered to provide a balance between strength and flexibility. This allows the panels to withstand moderate impacts without cracking or delaminating. In real - world scenarios, this means that the panels can resist damage from minor collisions, such as those caused by moving equipment or accidental knocks.

The Influence of Core Material

The core material of fire retardant ACP also has a significant impact on its impact resistance. Our non - combustible cores are designed to enhance the panel's overall toughness and energy absorption capabilities. These cores are often made from materials such as mineral - filled polymers or fire - resistant foams, which can deform under impact and dissipate the energy.

When an impact occurs, the core material acts as a cushion, reducing the stress transferred to the aluminum skins. This helps prevent the skins from puncturing or buckling, thereby maintaining the integrity of the panel. In our High Gloss Ivory White ACP Sheet for Exterior, the advanced core material not only provides excellent fire retardancy but also contributes to superior impact resistance, making it suitable for exterior applications where the panels may be exposed to harsh weather conditions and physical impacts.

Testing and Certification

To ensure the reliability of our fire retardant ACP's impact resistance properties, we subject our products to rigorous testing procedures. These tests simulate real - world impact scenarios, such as falling objects or collisions, and measure the panel's response.

Our products meet or exceed international standards for impact resistance, such as ASTM D3029 or EN 14509. These certifications are a testament to the quality and performance of our fire retardant ACP. By adhering to these strict standards, we can guarantee that our customers receive panels that are not only fire - resistant but also capable of withstanding various impact forces.

Real - World Applications

The impact resistance properties of our fire retardant ACP make them suitable for a wide range of applications. In commercial buildings, the panels can be used for interior partitions, wall cladding, and ceilings. Their ability to resist impacts ensures that the building's interior remains intact and aesthetically pleasing, even in high - traffic areas.

For exterior applications, such as building facades and signage, the impact resistance of our ACP is crucial. It protects the panels from damage caused by wind - borne debris, hail, or accidental impacts during construction or maintenance. Our High Glossy Pure Color Aluminum Composite Panel For Kitchen Cabinets is also a popular choice for kitchen interiors, where it can withstand the rigors of daily use, including knocks from pots and pans.

Advantages of Our Fire Retardant ACP

In addition to excellent impact resistance, our fire retardant ACP offers several other advantages. Firstly, its fire - resistant properties provide an added layer of safety, reducing the risk of fire spread in buildings. Secondly, the panels are lightweight, which makes them easy to handle and install, reducing labor costs and installation time.

Moreover, our ACP products come in a wide range of colors and finishes, allowing for endless design possibilities. Whether you're looking for a sleek, modern look or a more traditional aesthetic, we have the perfect panel to meet your needs.

Conclusion

The impact resistance properties of fire retardant ACP are a crucial factor to consider when choosing building materials. Our products, with their carefully engineered aluminum skins and advanced core materials, offer superior impact resistance, ensuring long - lasting performance and durability.

If you're in the market for high - quality fire retardant ACP, we invite you to contact us for a detailed discussion about your project requirements. Our team of experts is ready to assist you in selecting the right panels and providing you with all the necessary information. Whether you're a contractor, architect, or building owner, we can help you find the perfect solution for your next project.

References

- ASTM International. (20XX). ASTM D3029 - Standard Test Method for Impact Resistance of Flat - Backed Decorative Plastic Laminates.

- European Committee for Standardization. (20XX). EN 14509 - Aluminium composite panels for facades - Requirements and test methods.