As a seasoned supplier of Alucobond cladding, I've often been asked whether this versatile material can be used in coastal areas. It's a valid concern, considering the unique environmental challenges that coastal regions present. In this blog post, I'll delve into the characteristics of Alucobond cladding and explore its suitability for coastal applications.

Understanding Alucobond Cladding

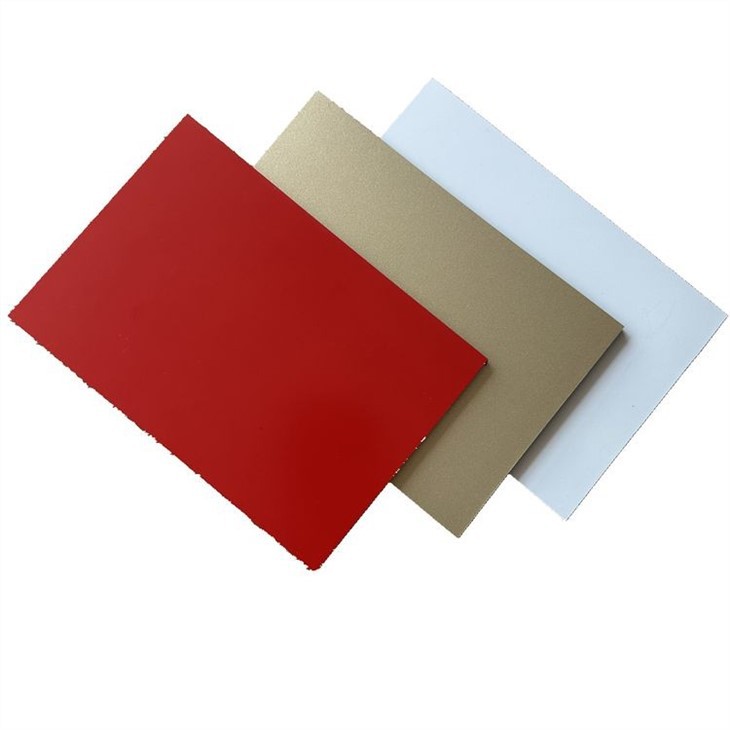

Alucobond is a composite material consisting of two aluminum sheets bonded to a polyethylene core. This combination results in a lightweight yet robust material that offers excellent durability, weather resistance, and design flexibility. Alucobond cladding is widely used in architectural projects for both interior and exterior applications, including facades, partitions, and signage.

One of the key advantages of Alucobond cladding is its ability to withstand a wide range of environmental conditions. The aluminum outer layers provide protection against corrosion, UV radiation, and extreme temperatures, while the polyethylene core offers insulation and impact resistance. Additionally, Alucobond cladding can be finished with a variety of coatings, including PVDF (polyvinylidene fluoride), which further enhances its durability and weather resistance.

Challenges in Coastal Areas

Coastal areas are characterized by high humidity, saltwater exposure, and strong winds, which can pose significant challenges to building materials. Saltwater is highly corrosive and can cause metal to rust and deteriorate over time. High humidity levels can also promote the growth of mold and mildew, which can damage the appearance and integrity of the cladding. Strong winds can exert significant pressure on the building envelope, potentially causing the cladding to loosen or detach.

In addition to these environmental challenges, coastal areas are often subject to strict building codes and regulations to ensure the safety and durability of structures. These codes may require the use of specific materials and installation methods to withstand hurricane-force winds, storm surges, and other natural disasters.

Suitability of Alucobond Cladding in Coastal Areas

Despite the challenges posed by coastal environments, Alucobond cladding can be a suitable choice for coastal applications when properly specified and installed. Here are some factors to consider when evaluating the suitability of Alucobond cladding in coastal areas:

Corrosion Resistance

The aluminum outer layers of Alucobond cladding provide excellent corrosion resistance, making it suitable for use in coastal areas. However, it's important to choose a cladding with a high-quality PVDF coating, which offers superior protection against saltwater corrosion. PVDF coatings are highly resistant to UV radiation, chemicals, and abrasion, and can maintain their color and finish for many years.

Weather Resistance

Alucobond cladding is designed to withstand a wide range of weather conditions, including high humidity, strong winds, and extreme temperatures. The polyethylene core provides insulation and impact resistance, while the aluminum outer layers protect against UV radiation and moisture. Additionally, Alucobond cladding can be installed with a ventilated rainscreen system, which allows moisture to escape and helps prevent the growth of mold and mildew.

Structural Integrity

Coastal areas are often subject to strong winds and seismic activity, which can exert significant pressure on the building envelope. Alucobond cladding is lightweight yet robust, and can be installed using a variety of attachment methods to ensure its structural integrity. It's important to choose a cladding system that is designed to withstand the specific wind and seismic loads of the coastal area.

Design Flexibility

Alucobond cladding offers a wide range of design options, including different colors, finishes, and textures. This allows architects and designers to create unique and visually appealing facades that complement the surrounding environment. Additionally, Alucobond cladding can be formed into a variety of shapes and sizes, making it suitable for complex architectural designs.

Case Studies

To illustrate the suitability of Alucobond cladding in coastal areas, here are some case studies of successful projects:

[Project Name 1]

This coastal resort in [Location] features a modern facade clad in Alucobond panels with a PVDF coating. The cladding provides excellent protection against saltwater corrosion and UV radiation, while the ventilated rainscreen system helps prevent moisture buildup and mold growth. The project was completed on time and within budget, and has received positive feedback from the client and the local community.

[Project Name 2]

This commercial building in [Location] is located in a high-wind area and was designed to withstand hurricane-force winds. The facade is clad in Alucobond panels with a custom-designed attachment system that provides additional structural support. The cladding has performed well during several severe weather events, and has maintained its appearance and integrity over time.

Conclusion

In conclusion, Alucobond cladding can be a suitable choice for coastal applications when properly specified and installed. Its corrosion resistance, weather resistance, structural integrity, and design flexibility make it a versatile and durable option for coastal buildings. However, it's important to work with a reputable supplier and installer who has experience in coastal projects, and to ensure that the cladding system meets the specific requirements of the coastal area.

If you're considering using Alucobond cladding in a coastal project, I encourage you to [Contact Us] to discuss your options and learn more about our products and services. We have a team of experts who can help you choose the right cladding system for your project, and provide you with the support and guidance you need to ensure a successful installation.

References

- [Reference 1]: [Title of Reference 1], [Author of Reference 1], [Publication Date of Reference 1]

- [Reference 2]: [Title of Reference 2], [Author of Reference 2], [Publication Date of Reference 2]

- [Reference 3]: [Title of Reference 3], [Author of Reference 3], [Publication Date of Reference 3]

If you're interested in our Alucobond cladding products, we offer a wide range of options, such as the 4mm ACP Aluminum Composite Panel With PVDF Coating For Exterior Wall Cladding, Interior Wall Panel PVC Marble Carbon Crystal Bamboo Fiber Board Charcoal Panel, and PVDF Aluminum Composite Panels ACP Sheet. Feel free to reach out to us for more information and to start the procurement and negotiation process.