Linyi Alux Building Material Co.,Ltd

Linyi Alux Building Material Co.,Ltd. is a 25 years'factory founded in 1998, which mainly produces aluminum composite panel with 8 ACP production lines. We created our trading company Linyi Alux Import and Export Co.,Ltd. in 2018, exported to the whole Asian, African countries, Middle east, and the North and South America.

Why Choose Us

Rich Experience

Providing technical support, troubleshooting, and maintenance services.

One-stop Solution

Support to customers to ensure a smooth transaction.

Production Market

Exported to the whole Asian, African countries ,Middle east, and the North and South America.

Our Service

Our service runs throughout the whole production process from the pre-sales, product design, production and after-sales.

-

1500x3000mm Acp/acm Sheet For Interior Or Exterior Wall C...

Aluminum composite panels for billboards, printing Add to Inquiry -

Mirror ACP Aluminum Composite Panel

Aluminum composite panels for billboards, printing Add to Inquiry -

Digital Print Advert Signs Aluminium Composite Panel

●Protective film to protect panel surface. Add to Inquiry -

OEM Protective Film Wholesale Composite Aluminum Panel

Interior wall aluminum-plastic composite panel series:Aluminum thickness: 0.21mm, 0.18mm, 0.15mm, Add to Inquiry -

Hot Sale Free Sample PE/PVDF Alucobond/Aluminum Composite...

Hot Sale Free Sample PE/PVDF Alucobond/Aluminum Composite Panel/ACP Made In China Specifiction Add to Inquiry -

Aluminium Composite Panel ACP Sheet Wall Cladding ACM

ACP ACM Sheet Building Materials . Aluminium Composite Panel Price Add to Inquiry -

3*0.15mm Mirror Aluminum Composite Panel ACM

Mirrored Aluminum Composite Panel Products Description 1) Top: aluminum alloy(3003) coated with Add to Inquiry -

Factory Mirror Color Aluminum Composite Panels 1220*2440m...

The aluminum-plastic composite panel is composed of multiple layers of materials. The upper and Add to Inquiry -

Factory Price Silver Mirror Aluminum Composite Panel 1220...

Products Description Aluminum plastic sheet, also known as aluminum composite panel, is a type of Add to Inquiry -

Mirror Alubond ACP Sheet Aluminum Exterior Panel ACP Pane...

Mirror Aluminum Composite Panel Product IntroductionMirror aluminum composite panel, also known as Add to Inquiry -

3mm Aluminum Plastic Composite Panel Mirror Colors For In...

3mm Aluminum Plastic Composite Panel Mirror Colors For Interior Design Our aluminum coils: Add to Inquiry -

Acceptable Special Size Mirror Decorative ACP For Front D...

At present, the most exported regions are the Americas, Europe, Southeast Asia and other regions. Add to Inquiry

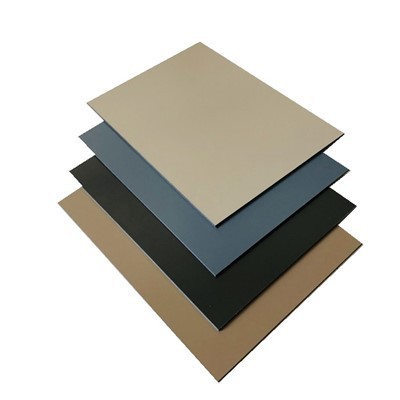

Description of Mirror Aluminum Composite Panel

The front side of the mirror finished aluminum composite panel is treated like a mirror. The panel looks more beautiful and widely used in interior decoration, kitchen, especially in ceiling and household appliance and furniture etc.

The mirror finished aluminum composite panel can be used for interior wall decoration, low building cladding, shop face decoration, partitions interior decorations, and more. This building material is also ideal for use in billboards, signboards, ceiling, eaves, balconies, kitchen, bathroom, galleries, tunnels, subway interiors and other entertainment places.

Feature of Mirror Aluminum Composite Panel

The mirror finished aluminum composite panel has advantages like simple cleaning, easy maintenance, elegancy and magnificence, good flexibility, easy processing and fabricating performance, easy installation, light weight, high strength, extreme rigidity, superior impact resistance, excellent surface flatness and smoothness, good heat insulation, sound insulation, acid-resistance, alkali-resistance, good weatherproofing and non-resonance, various uniform colors, and more.

Application of Mirror Aluminum Composite Panel

Mirror aluminum composite panel is a type of composite material made of a core layer of low-density polyethylene (LDPE) sandwiched between two layers of aluminum sheets. The front aluminum sheet is coated with a reflective mirror-like finish, giving it a highly reflective surface that can be used for various applications.

Mirror aluminum composite panels come in various sizes, thicknesses, and colors, allowing designers and architects to create unique and eye-catching designs. They can be cut, bent, and shaped to fit specific design requirements, making them a versatile and flexible material for various applications.

|

Specifications Of Aluminum Composite Panel |

|

|

Normal Width |

1220mm, 1250mm, 1500mm, 1550mm, 1570mm, Max 2000mm |

|

Panel Length |

2440mm ,5000mm,5800mm ,normally within 5800mm. |

|

Or cut as required |

|

|

Panel Thickness |

2mm 3mm 4mm 5mm 6mm 8mm 10mm etc… |

|

Aluminum Alloy |

AA1100,AA3003,AA5005 …(Other Grade On Requirement) |

|

Aluminum Thickness |

0.08mm 0.10mm 0.15mm 0.21mm 0.3mm 0.4mm 0.5mm |

|

Coating |

PE coating , PVDF coating, NANO, Brush surface, mirror surface |

|

PE Core |

Recycle PE Core/Fireproof PE Core/Unbreakable PE Core |

|

Color |

Metal/Matt/Glossy/Nacreous/Nano/Brushed/Mirror/Granite/Wooden |

|

Core Material |

HDP LDP Fire-proof |

|

Delivery |

Within two weeks after receiving deposit |

|

MOQ |

500 Sqm per color |

|

Brand/OEM |

Aluwedo/Customized |

|

Payment Terms |

T/T, L/C at sight, D/P at sight,Western Union |

|

Packing |

FCL:In bulk;LCL:In Wooden pallet Package;according customers' requirement |

- Constructional exterior curtain walls, Wall Panel are widely used in exhibition, stores, ofices.banks, hotels,restaurants and apartments,

- Decorative renovation for storey-added old buildings, facades, roofing;

- Indoors decoration for interior walls, ceilings, bathrooms, kitchens, balconies and subway,

- Advertisement board, display platforms, billboards and signboards;

- Wallboard and ceiings for tunnels.

- Raw materials in industrial purpose.

How aluminum is obtained

Aluminum is the third most common element found in the Earth's crust. In its natural state it is found in many silicates, and is extracted from the mineral known as bauxite, a sedentary rock with a high aluminum content.

As a metal, its low density and resistance to corrosion, in addition to being a good conductor, make it an extremely useful element for many industrial processes.

Currently, with China leading the way as a producer, it is estimated that around 60,000 metric tons are produced annually, of which 20% comes from recycling.

Main characteristics of aluminum

Among its common uses, as incredible as it may seem, is the manufacture of mirrors (thanks to its optical properties), containers and cans or, of course, as aluminum foil for domestic use. It has multiple alloy standards that adapt to sectors as diverse as the automotive, telephone or construction industries.

Aluminum can be easily combined with other materials to produce new materials such as those used in cartons or composite panels.

Composition and preparation of the composite panel

The composite panel is a material composed of two aluminum sheets and an inner core made of thermoplastic base that can accommodate mineral load. It is specially designed for both newly built ventilated facades and for their renovation or rehabilitation. Its manufacturing standard consists of an outer sheet of 5005 aluminum alloy and an inner sheet of 3105.

It is divided into two groups depending on the mineral load of its core, and can be non-combustible or fireproof, and is classified (in accordance with the UNE 13501-1:2007 standard) as A2-s1, d0 and B-s1, d0.

The composite panel is produced through a continuous lamination process, in which a sheet of the material that will make up the core is extruded and compacted between two aluminum sheets that are unrolled at the same time. Finally, it is compacted and the flatness of the material is perfected and a protective film is applied.

Uses of aluminum composite panel

As we have already mentioned, its most common use is in ventilated facades, a type of multi-layer coating system that stands out for its great effectiveness in solving the insulation, thanks to the thermal behavior it achieves from the building.

The most curious thing about the ventilated façade is that it allows the creation of a chimney effect between its layers that generates continuous ventilation in the chamber, maintaining a stable temperature that results in greater energy efficiency compared to more conventional systems. Thus, during the summer, heat is expelled, renewing the circulating air. In winter, air circulation slows down, conserving heat inside the building.

Currently, the aluminum composite panel can be transformed into multiple possibilities. Among them is punching, which allows the creation of pointillist-type shapes on the surface of the panel, creating drawings or shapes; roller bending, to achieve curved shapes; CNC stamping and engraving to create reliefs; 3D shaping to project volumes on a flat surface, etc.

This transformation capacity of the aluminum composite panel gives it extra versatility when it comes to being used for constructions with risky and creative designs.

It also makes it an ideal material to combine and create areas of the façade that would be impossible with other materials.

Beyond the usual image of a flat ventilated façade, we see how the panel can be used for other types of more striking projects and risky designs that contribute to giving buildings a special character.

4 Facts About Aluminum Composite Panels

Aluminum Composite Panels, commonly known as ACP, represent a prevalent building material with diverse applications in both construction and signage. Comprising two thin, flat aluminum panels adhered to a non-aluminum center, this material often goes unnoticed in our daily lives. Despite its inconspicuous presence, aluminum composite panels offer intriguing facets that may not be widely known. Here are four noteworthy facts shedding light on the versatility and benefits of aluminum composite panels.

Extensive Color Options

Aluminum composite panels boast a palette of nearly 40 different colors, with the added flexibility of customization to suit specific building applications. Designers can emulate the appearance of aluminum, copper, zinc, or stainless steel, providing unparalleled design versatility characterized by clean and modern lines that endure the test of time. This diversity makes aluminum composite panels a unique choice, challenging to match in terms of aesthetic adaptability.

Remarkable Lightweight Characteristics

Following a complete installation, the finished weight of an aluminum composite panel averages a mere 2.5 pounds per square foot. This remarkable lightweight attribute coexists with exceptional durability and longevity, distinguishing it from alternative materials. The combination of structural resilience and reduced weight contributes to the practicality and ease of handling during the installation process.

Environmental Sustainability

Opting for construction with aluminum composite panels aligns with environmental responsibility, given that these panels are considered sustainable building materials. Typically crafted from approximately 85% recycled aluminum, these panels contribute to reducing environmental impact. Moreover, certain states may offer tax credits for such eco-friendly choices, while LEED credits from the U.S. Green Building Council may be attainable for buildings voluntarily incorporating aluminum composite panels. This underscores the commitment to sustainable construction practices.

Fire Resistance Compliance

Addressing global building codes, aluminum composite panels are available with cores composed of fire-resistant materials. Specifically engineered to meet stringent codes applicable to large structures such as skyscrapers and high-rise buildings, these panels ensure the use of non-combustible materials in adherence to building regulations. Prospective buyers should scrutinize the fire specifications of specific aluminum composite panels to ascertain compliance with their state's code requirements, emphasizing safety in building applications.

In the realm of construction, integrating Aluminum Composite Panels requires meticulous attention to detail. BIM Model Coordination, incorporating these panels seamlessly into Building Information Modeling (BIM), enhances the precision of design and construction processes. Ensuring the accurate representation of aluminum composite panels within a BIM model facilitates effective collaboration among stakeholders, promoting a streamlined and efficient construction workflow. Thus, the integration of Aluminum Composite Panels into BIM Model Coordination enhances project accuracy and efficiency, reflecting a forward-thinking approach to modern construction practices.

Best Places to use Aluminum Composite Panels (ACM)

Aluminum composite material (ACM) is a three-layer panel material made of two thin layers of pre-finished aluminum bonded on either side of a polyethylene (PE) core. ACM panels are used in many indoor and outdoor applications due to their excellent dimensional stability, lightweight, strength, and durability. Piedmont Plastics offers aluminum composite panels in a wide choice of size, thickness, finish, and color. We also have fire grades available, and you can have your aluminum composite panels cut-to-size and machined into fabricated parts to meet your manufacturing needs.

Ways To Use Aluminum Composite Panels

Between its aesthetic qualities and ability to be easily fabricated without sacrificing durability, ACM is a popular choice for material for a wide range of products. Some of its many uses include channel letters for signage, point-of-purchase displays, exhibition kiosks, digital and screen printing, performance sets, specialty vehicles, and building and construction applications like architectural cladding, insulation, and wall linings.

In manufacturing, ACM solves a lot of challenges by being simple to machine and fabricate. It bonds quickly and exhibits excellent dimensional stability. Panels can come in custom shapes and sizes, suitable for cutting, shearing, bending, punching, drilling and profiling. They can be cut to satisfy customer needs beforehand and can come in a wide range of colors—or, in some cases, be color-matched to fit a company's branding or design requirements.

ACM readily accepts traditional inks and paints for signage and display applications, is digitally printable, and works well with PSA print media. Additionally, ACM meets UL compliance per UL879 as a component for sign accessories and may be used to construct type II electrical enclosures—all critical things to consider when planning exhibition hall displays.

When used in building, aluminum composite panels can add a modern touch to structures by allowing for shapes that would be considered an insurmountable design challenge decades ago. In addition, aluminum composite panels are significantly easier to work with when compared to more traditional materials such as steel, wood, and concrete.

Advantages of Aluminum Composite Material (ACM)

One of the most beneficial features of ACM is its versatility. ACM panels can be easily cut, routed, fabricated, mounted, and installed with everyday tools. ACM panels remain flat over time and are approximately half the weight of traditional aluminum. Because of this, ACM is considered more cost-effective than similarly gauged aluminum sheets.

As materials go, ACM is highly resistant to ultraviolet light, scratches, weather, and corrosion. This makes it perfect for a wide variety of applications. On top of that, ACM can be easily cleaned and maintained, allowing it to maintain a sleek and brilliant look. Where other materials may deteriorate over time, aluminum composite panels last much longer and provide end-users with more value for less cost.

Certificate

Our Factory

We created our trading company Linyi Alux Import and Export Co.,Ltd. in 2018 , exported to the whole Asian, African countries ,Middle east, and the North and South America. With an annual export volume of 1.5 million US dollars, we are the largest Aluminum Composite Panel exporter in northern China.

FAQ

We're professional mirror aluminum composite panel manufacturers and suppliers in China, specialized in providing high quality customized service. If you're going to buy discount mirror aluminum composite panel in stock, welcome to get pricelist and free sample from our factory. Good service and low price are available.

Tawny Mirror ACP for Interior Decoration, wood acp sheet, cladding acp