Linyi Alux Building Material Co.,Ltd

Linyi Alux Building Material Co.,Ltd. is a 25 years'factory founded in 1998, which mainly produces aluminum composite panel with 8 ACP production lines. We created our trading company Linyi Alux Import and Export Co.,Ltd. in 2018, exported to the whole Asian, African countries, Middle east, and the North and South America.

Why Choose Us

Rich Experience

Providing technical support, troubleshooting, and maintenance services.

One-stop Solution

Support to customers to ensure a smooth transaction.

Production Market

Exported to the whole Asian, African countries ,Middle east, and the North and South America.

Our Service

Our service runs throughout the whole production process from the pre-sales, product design, production and after-sales.

-

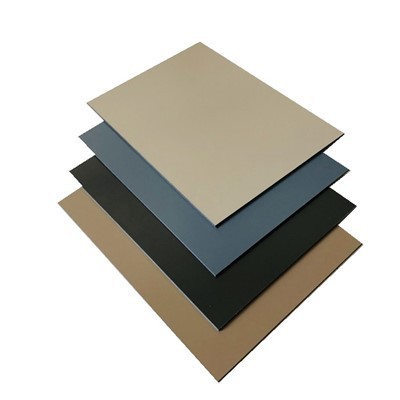

Glossy Aluminum Composite Panel For Signage

Aluminum plastic composite board is composed of multiple layers of materials, with high-purity Add to Inquiry -

Building Materials High Glossy Aluminum Composite Panels

Aluminum Composite Panels also clled ACP Add to Inquiry -

Green Glossy ACP For Wall Cladding

Export 3/4mm Wholesale Aluminum Sanwich Materials Add to Inquiry -

ACP Glossy 4x8 FT For Furniture

ACP Glossy 4x8 FT For Furniture3mm/4mm Add to Inquiry -

3mm Composite Aluminum Panel Alucobond

Alucobond is a popular and sought after material in the construction industry due to its Add to Inquiry -

3mm Glossy Aluminum Composite Panel ACM

Double-layer aluminum skin, PE sandwich Add to Inquiry -

4mm Composite Panel Aluminum Signage/Wall Cladding

Wood grain aluminum composite board cladding kitchen cabinet. Add to Inquiry -

Aluminum Composite Panel Used For Signage

According to the design drawing, slot and bend the aluminum composite panel to create a sign letter Add to Inquiry -

Aluminum Composite Material Interior Exterior

Aluminum composite panels for Interior Exterior Add to Inquiry -

Glossy Aluminium Composite Panel For Interior/Exterior De...

Pls offer your brand or LOGO design to us, then we could produce all goods with your brand or Add to Inquiry -

High Glossy Aluminium Composite Panel For Billboards

① Exterior wall aluminum-plastic composite panel series:Aluminum thickness: 0.30mm, 0.35mm, 0.40mm, Add to Inquiry -

High Gloss Aluminum Plastic Panel ACM Sheet

As a new type of decorative material, aluminum-plastic composite panel (also known as Add to Inquiry

The High gloss aluminum composite panel have been in high demand over the last few years. As a matter of fact,this is because of the fact that the sign boards represent quite diverse options with consistent features. The most common applications of high gloss sign boards would be the usage in wall cladding & roof edging, billboards & signs, used in shop fronts and interior and external wall cladding. However,one of the biggest advantages of high gloss sign boards is the fact that they come out in a variety of colors for this sole reason ,and the usage of high glass color sign boards is quite common in the realm of marketing such as billboards.

It has the features of excellent surface flatness and smoothness,various uniform colors,simply cleaning,fire-resistance and can be easily processed. The high gloss aluminum composite panel are generally used in advertisement board,signboards,wallboard,ceiling and constructional exterior curtain walls. The processing of making high gloss aluminium composite sheet panel is to use a heat-conducting epoxy layer filled with aluminum to bond flat ribs to a grooved base plate of extrusion. Therefore, the surface of high gloss aluminum composite panel will be more uniform.

Features

Sandwich panel construction techniques have experienced considerable development in the last 40 years. Previously, sandwich panels were considered products suitable only for functional constructions and industrial buildings. However, their good insulation characteristics, their versatility, quality and appealing visual appearance, have resulted in a growing and widespread use of the panels across a huge variety of buildings. What features does the Aluminum Composite Panel have?

- Super peeling strength

- Excellent surface flatness and smoothness

- Superior weather, corrosion, pollutant resistance

- Even coating, various colors

- Fireproof, excellent heat and sound insulation

- Superior impact resistance

- Lightweight and easy to process

- Easy to maintain, self-clean

What are Aluminum Composite Panels Used For?

Nowadays, the aluminum composite panel was used in many area, it is common in our life, However, not all the people was familiar to this building wall material, The use of aluminum composite panels is multifaceted, so I will introduce the specific use of aluminum composite panel in this article.

The aluminum composite panel is a composite building material which is processed on a special production equipment by using a chemically-coated aluminum sheet as a surface material and a polyethylene plastic as a core material.

The unique properties of the aluminum composite panel determine its wide range of uses: it can be used for building exterior walls, curtain wall panels,old building renovation, interior wall and ceiling decoration, advertising signs, display stands, purification and dust prevention. engineering.

The aluminum composite panel is made of polyvinyl chloride resin as a base material, adding a certain amount of anti-aging agent, modifier and other additives, and is prepared by mixing, calendering, vacuum absorbing and the like.It has the advantages of light weight, moisture proof, heat insulation, non-flammable, non-dusting, easy to clean, can be painted, easy to install, and low in price.

Concisely, The use of aluminum composite panels are :

1. The exterior wall of the building and the curtain wall panel.

2. The exterior of the old building was modified and refurbished.

3, Balcony, equipment unit, indoor compartment.

4. Panel, signage board and display stand.

5, Interior wall decorative panels, ceilings, advertising signs.

6, The body of industrial materials, cold storage car body.

The aluminum composite panels are divided into indoor panels and outdoor panels. The surface coatings of the two panels are different, which determines the different occasions for which they are applicable.

Indoor aluminum composite panels

The surface of the indoor aluminum composite panels is usually coated with a resin coating. This coating

can not adapt to the harsh outdoor environment. If it is used outdoors, it will naturally accelerate the aging

process and cause discoloration and discoloration.

Outdoor aluminum composite panels

The surface coating of the outdoor aluminum composite panels is generally coated with a polyfluorinated elastomer which is resistant to aging and ultraviolet rays, and the sheet is expensive.

What Are the Precautions for Daily Maintenance of Aluminum Composite Panels?

Aluminum-plastic panel, also known as aluminum-plastic composite panel, is a composite material composed of aluminum and polyethylene plastic, polyethylene as the core material, coated aluminum plate as the surface material. Aluminum-plastic panels have many excellent properties in applications, such as good decoration, weather resistance, corrosion resistance, impact resistance, fire protection, moisture resistance, sound insulation, heat insulation, etc., so they can play a good role in various industrial life.

What are the precautions for daily maintenance of aluminum-plastic panel:

First, for aluminum-plastic panels in the use period, regular inspection and maintenance are necessary.

As we all know, in the use of aluminum-plastic panels, often due to air humidity and wind and sun exposure, aluminum-plastic panels deformation and rust phenomenon, or because of some external factors caused by damage to aluminum-plastic panels and so on. At this time, the user needs to timely carry out the necessary repair and maintenance of these aluminum-plastic panels, so as to ensure the normal service life of the aluminum-plastic panels.

Second, it is necessary to frequently clean and maintain the aluminum-plastic board.

The long-term use of aluminum-plastic board, its surface will gather some dust and oil, so it is necessary to regularly carry out the necessary cleaning and maintenance of the aluminum-plastic board, otherwise it will seriously affect the service of the aluminum-plastic board. Note: When cleaning and maintaining aluminum-plastic panels, it is necessary to choose some soft fabrics to gently wipe them.

Third, the aluminum-plastic panel should be placed away from the water source as far as possible.

Aluminum-plastic board is easier to deform, especially in humid air or environment, it will be more likely to deform, so the aluminum-plastic board should be placed away from the water source to keep it in a dry environment.

Advantages of the Aluminium Composite Panel

The aluminium composite panel has many advantages when compared to other solutions on the market, such as sandwich panels, phenolic resin panels and even the more classic ones such as ceramic or natural stone. And when we talk about other façade insulation solutions such as ETICS (External Thermal Insulation Composite System), or when we compare it directly with façades without cladding, ventilated façades made with aluminium composite panels are the clear winners in terms of structural lightness, low maintenance costs and, above all, energy savings.

Let's take a look at the most important advantages.

Versatile, quality design

The composite panel has a good surface finish, a variety of textures and colours and its formal freedom makes it suitable for a wide range of locations, buildings and aesthetics.

It also has a wide range of machining and installation options. The material can be cut, drilled, punched, stamped, milled, curved and bent with the most common adapted tools on the industry.

Excellent thermal and acoustic insulation

Another positive aspect is its thermal and acoustic insulation capacity. If we install a ventilated façade type installation, we will achieve thermal and acoustic insulation more in line with current energy efficiency and soundproofing specifications.

Fire safety

One of the best things about composite panels is that they can be non-flammable or non-flammable, so that they can meet the fire safety requirements of each country.

This is one of the most important aspects when you consider that the standards for building materials are getting stricter and stricter and that it can also save lives.

Lightweight and corrosion and shock resistant

Thanks to its combination of materials, it is light but at the same time strong, which makes it very easy to handle and assemble.

It is also highly protected against corrosion thanks to the available painted finishes, which can be adapted to all weather conditions.

Recyclable and long-lasting

Aluminium composite panels do not release any environmentally harmful substances at any time during their life cycle.

And the best thing is that after a long service life, they are fully recyclable and can be returned to the cycle of recycled materials.

Complies with current regulations and is easily adaptable

With the composite panel and a ventilated façade, the current energy and protection directives can be met without any problems.

In addition, manufacturers of this material can obtain country-specific building certifications, so that it can be used safely and efficiently in many more buildings.

The most common use is as a material for the installation of ventilated facades, which give the building a modern and functional appearance.

Other uses for which composite panels can also be used are:

- For cladding all types of facades.

- For interior spaces.

- For restoration and rehabilitation.

- For covering columns.

- Balcony cladding.

- Functional and aesthetic elements such as cantilevers and canopies.

- A multitude of industrial uses, such as in the automotive industry.

ACM Panels: Aluminium Composite Panel Wall Systems Guide

Architects, designers, builders, and developers can use Aluminum Composite Material (ACM) panels and Aluminum Composite Panels (ACP) for interior and exterior building and signage applications.

ACM panel systems provide high strength, low weight, good dimensional stability, and a sleek, modern appearance. ACM panels are an aesthetically versatile and easy-to-install alternative to aluminum or wood sheets.

Read on to explore how ACM panels systems' many features, benefits, and applications can help you achieve the structural and aesthetic needs of your next building or signage project.

What is an Aluminum Composite Material (ACM) Panel?

ACM panels provide building owners and developers with a stylish and practical product that can be utilized for renovation and new construction projects.

Aluminum composite material panels include two thin, pre-painted flat aluminum composite panels bound to a non-aluminum core center. Manufacturers combine natural fibers extracted from plants and animals with aluminum foil to produce an aluminum composite, which creates a more effective, robust, flexible, and aluminum composite than those made with synthetic fibers. Manufacturing the composite panel system involves a continuous lamination process of compacting the core between two aluminum sheets, then flattening the product and applying a protective coating.

Manufacturers offer two material choices for the core: Polyethylene (PE) and fire retardant cores.

PE cores offer a less expensive, lightweight option for buildings up to two stories tall.

While more costly, fire-retardant core ACM panels help meet the fire-retardant requirements for multi-story construction.

Surface Finishes and Coating Options Available for ACM Panels

ACM panels come in limitless color combinations, surface finishes, and thicknesses and allow routing, cutting, and roll-forming, which gives architects and designers endless aesthetic freedom.

Durability and Weather Resistance of ACM Panels

Several features of ACM panels make them long-lasting:

- The fluorocarbon coatings of ACM panels make them resistant to extremely high temperatures, wear and tear, harsh weather, and pollution.

- ACM panels' flexible plastic core prevents warping and distortion, which provides long-term durability, rigidity, and stiffness in any climate.

- The non-corrosive nature of aluminum makes ACM panels ideal for external facades and signage.

- High wind-resistant ACM panels with lighter weight make them suitable for signage and high-rise cladding.

- Its resistance to humidity prevents water-related damage.

- Easy to transport and install

- Lessens the wall framing and foundation load, which contributes to the structure's durability and longevity

- Building components use less material for construction cost savings

Certificate

Our Factory

We created our trading company Linyi Alux Import and Export Co.,Ltd. in 2018 , exported to the whole Asian, African countries ,Middle east, and the North and South America. With an annual export volume of 1.5 million US dollars, we are the largest Aluminum Composite Panel exporter in northern China.

FAQ

We're professional high gloss aluminum composite panel manufacturers and suppliers in China, specialized in providing high quality customized service. If you're going to buy discount high gloss aluminum composite panel in stock, welcome to get pricelist and free sample from our factory. Good service and low price are available.

B grade fireproof acp, High Gloss Composite Aluminium Cladding, A grade fireproof acp