Linyi Alux Building Material Co.,Ltd

Linyi Alux Building Material Co.,Ltd. is a 25 years'factory founded in 1998, which mainly produces aluminum composite panel with 8 ACP production lines. We created our trading company Linyi Alux Import and Export Co.,Ltd. in 2018, exported to the whole Asian, African countries, Middle east, and the North and South America.

Why Choose Us

Rich Experience

Providing technical support, troubleshooting, and maintenance services.

One-stop Solution

Support to customers to ensure a smooth transaction.

Production Market

Exported to the whole Asian, African countries ,Middle east, and the North and South America.

Our Service

Our service runs throughout the whole production process from the pre-sales, product design, production and after-sales.

-

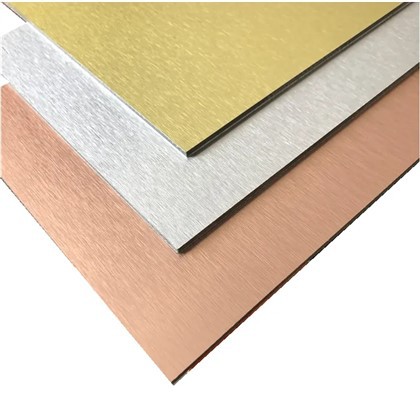

Factory 1.22*2.44m Acp Sheet Panel

Export 3/4mm Wholesale ACP Sheet Add to Inquiry -

Aluminum Composite Panel Supporting Service Silicone Glue

Silicone Glue used to install aluminum composite panels Add to Inquiry -

4mm PVDF Fireproof Metal Composite Materials

Outdoor curtain wall Add to Inquiry -

4*0.5mm PVDF Fireproof Metal Composite Materials

Exterior Wall Add to Inquiry -

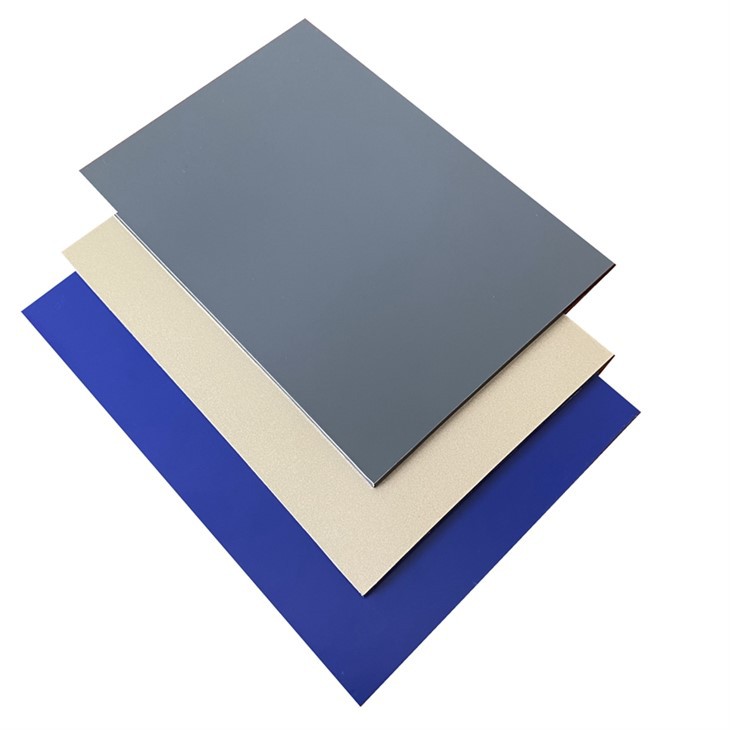

4*0.5MM Fireproof Aluminum Composite Panel ACM Sheet

Exterior Wall Add to Inquiry -

Fireproof ACP ACM Panel Aluminum Compoaite Panel

Aluminum Composite Panels also knows as ACP ACM. Add to Inquiry -

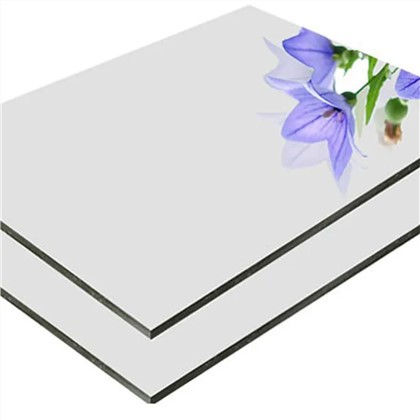

Factory Sale ACP Double Sided Aluminum Composite Panel

Factory Sale A2 Weather Resistance ACP Double Sided Aluminum Composite Panel Products Description Add to Inquiry -

920 X1785mm Fireproof Aluminum Composite Panels ACP ACM S...

As a new type of decorative material, aluminum-plastic composite panel (also known as Add to Inquiry -

4mm PVDF Finish ACP Aluminum Composite Panel Curtain Wall

Building Material Covering 4mm PVDF Finish ACP Aluminum Composite Panel Curtain Wall Product Add to Inquiry -

PE PVDF Fireproof Alu Cladding ACP Sheets Aluminum Compos...

aluminum plastic panel is a fantastic building material that offers a winning combination of style, Add to Inquiry -

Fireproof Aluminum Composite Panel B2 Grade ACM ACP Wall ...

Fireproof aluminum composite panel, also known as ACP, is a type of material that is commonly used Add to Inquiry -

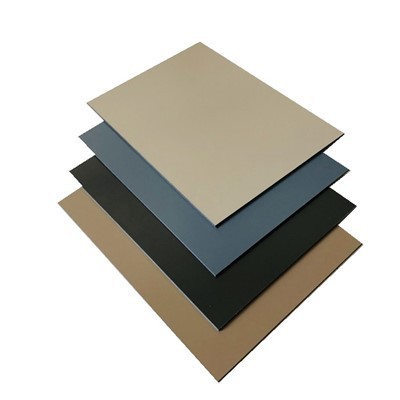

Wall Decoration Material PVDF 4mm Aluminum Composite Panel

Aluminum composite panel is a new material after a serious of processing aluminum sheet is used as Add to Inquiry

It Fireproof Aluminum Composite Panel adopts flame-retardant core material, and the combustion performance of the product reaches the refractory grade (class B1) or non-combustible grade (class A).

Application and features

Key highlights incorporate a totally smooth and level surface of the panel. The component of the structure that is significant for the evenness is the covering. Besides, the Fluorocarbon (PVDF) has another significant job, climate obstruction. The highlights of fire-evaluated aluminum composite panel items represent its wide region of use. Today, we can even discuss warmth and sound protection, just as fire obstruction on account of various coatings, for the most part the PVDF. This opens new skylines with respect to the utilization of the facade aluminium composite panel panels. Thus, territories of the utilization of the Fluorocarbon (PVDF) aluminum composite panels are wide. Today, we, for the most part, use it as a crude material in various types of enterprises. Plus, it is utilized for notice sheets and claddings, exteriors, for example, outsides of structures.

Also, facade aluminium composite panel types are reasonable for conditions that require a high fireproof evaluation. These panels are a decent decision when it is important to improve the wellbeing of individuals and creatures, the structure itself, and the earth.

Fireproof Aluminum Composite Panel Structure

These are the most prominent features of fire-rated aluminum composite panel products

Structure

Polymeric film composites on the aluminum center

FR center is produced using fireproof evaluation materials.

Defensive film that ensures the panel surface

Spotless or hued PVDF covering applied on the aluminum sheet

Thickness

The absolute thickness of the last item, for example, panel, relies upon the blend of the aluminum loop, covering, type and number of coatings, polymer film, just as different materials that can enter the structure of the panel. This material comes in different thicknesses. To be specific, fire-appraised aluminum composite panel items are fabricated by various makers and brands. For the most part, the exterior aluminum composite panel comes in 3, 4, 5, and 6mm thicknesses. Every thickness represents diverse physical and mechanical properties. To be specific, the thicker the panel the more noteworthy the quality and sturdiness of the specific panel. This is the reason they come in different structures.

Fluorocarbon (PVDF) Coating

This is one of the layers that consummately supplements the aluminum composite panel and its job. Fluorocarbon (PVDF) is a covering that is acquired by blending a few distinct segments. PVDF covering which is otherwise called the fluorocarbon covering is another significant component in the aluminum panel structure. Those incorporate fluorocarbon gums, primarily containing the fluorine compound, liquor, ester dissolvable, and paint. This covering is significant as it gives more quality and protection from the panel itself.

Fireproof Aluminum Composite Panel - What You Need to Know?

Fireproof Aluminum Composite Panel are not only easily machinable and flexible but also gives an ultra-modern look to the buildings. Available in a wide range of colours, textures and pattern, Fireproof Aluminum Composite Panel adds a touch of beauty to every surface it is pasted on. The sheets can also be customized to design and budgetary requirements.

Three elements are needed in proper combination before ignition and combustion can take place:

1. Air for oxygen supply

2. Fuel to burn

3. Ignition temperature to start and continue with the combustion process.

Features of fire rated ACP:

1. Sound absorbing.

2. Environment-Friendly

3. Ultra-modern

4. Durable and Beautiful

5. Fire and Dust Resistant

6. Fast Application

7. Corrosion Resistant

Understands that creating a sustainable earth is important to each and every person. The brand makes sure that the panels are composed of 100% recyclable materials which are minerals, aluminium and polymer. This helps a lot in conserving valuable resources of nature and making panels a complete boon to the environment. These environment-friendly products fall in the acceptability for all green building projects.

The fire rated ACP can resist fire for upto 2 hours. The main difference between fire-rated ACP and normal ACP sheets is that both are ACP but with different core materials. The mineral core is made up of about 70% inorganic materials such as Calcium Hydroxide and Magnesium Hydroxide and 30% polymer. The core of the normal ACP is LDPE/HDPE minerals whereas the fire rated ACP is made of the specially formulated fire resistant mineral core.

How do Aluminium Composite Panels Perform in Terms

Aluminium composite panels (ACPs) have been widely used in the construction industry for their aesthetic appeal, lightweight nature, and ease of installation. However, their fire resistance and safety performance have been a subject of concern in recent years. Let's discuss these aspects in more detail.

Fire Resistance

The fire resistance of ACPs depends on various factors, including the core material, the overall composition, and the installation methods. ACPs typically consist of two aluminium sheets bonded to a core material, which is often made of polyethylene (PE), fire-retardant (FR) material, or a mineral-filled core (such as non-combustible materials like stone or ceramic).

PE Core

ACPs with a polyethylene core are generally considered less fire-resistant. In the event of a fire, the PE core can melt and contribute to the spread of flames, potentially leading to rapid fire propagation.

FR Core

ACPs with a fire-retardant core offer improved fire resistance compared to those with a PE core. The FR core is designed to resist ignition and slow down the spread of flames, providing a certain degree of fire protection.

Mineral-Filled Core

ACPs with a mineral-filled core, such as those containing stone or ceramic, are typically the most fire-resistant option. These panels offer enhanced fire protection and are considered non-combustible.

Safety Measures

To enhance the fire safety of buildings using ACPs, several safety measures are recommended:

Building Codes and Regulations

It is essential to adhere to local building codes and regulations governing the use of ACPs. These regulations often specify the type of ACPs that are permissible and provide guidelines for installation and fire safety.

Fire-Retardant Coatings

Applying fire-retardant coatings or paints on ACPs can help improve their fire resistance. These coatings act as an additional layer of protection against flame spread and heat release.

Proper Installation

ACPs should be installed according to manufacturer guidelines and industry best practices. Proper installation includes using appropriate fixings, sealants, and fire-resistant barriers to prevent fire spread through gaps or joints.

Regular Inspections and Maintenance

Regular inspections of ACP installations are crucial to identify any signs of damage, deterioration, or improper functioning. Prompt maintenance and repairs are necessary to ensure the continued fire safety of the ACP system.

It's important to note that fire safety is a complex issue, and the performance of ACPs in real-life fire situations can depend on various factors, including the building design, fire detection and suppression systems, evacuation plans, and overall fire safety measures implemented in the structure.

To ensure fire safety and compliance, it is advisable to consult with fire safety professionals, architects, and local authorities who can provide specific guidance based on your project's requirements and the applicable building codes and regulations in your region.

Fireproof Aluminum Composite Panels, Why It Is So Popular?

(1)Fireproof panels also can be called fire rated aluminum composite panel or fire resistant aluminum composite panel. It adopts flame-retardant core material, and the combustion performance of the fireproof panels reaches the refractory grade (class B1) or non-combustible grade (class A).

(2)At the same time, other performance indicators must also meet the technical specifications of aluminum composite panels.

The production process of fireproof panels core material

The fireproof aluminum-plastic composite core material is made of polyethylene as the main raw material, adding halogen-free environmentally-friendly flame retardant, and adopting continuous activation equipment to refine the surface of the composite, and then adding flame retardant synergist and other additives. After fully mixing and plasticizing, the particles are extruded.

The characteristics of fireproof core material

The halogen-free fireproof aluminum-plastic plate core material is grayish white or white granules, which has the advantages of environmental protection, light weight and easy processing. It conforms to the development trend of international flame retardant materials and can meet the requirements of the building decoration industry. The fire rating reaches A grade or B. Level, fully meet the requirements of the aluminum composite panel production industry.

The Difference Between B1 Grade and A2 Grade Fire Resistant Aluminum Composite Panels

(1)The ingredients of fire core materials are different:

B1 grade plastic core:

It contains 55% – 55% flame retardant, the main ingredients are aluminum oxide (Al₂O₃) and magnesium oxide (MgO) ;

A2 grade fireproof aluminium composite sheet plastic core material :

It Contains 88% – 90% of the flame retardant, the main ingredients are aluminium hydroxide(Al(OH)3) and magnesium hydroxide (Mg(OH)2) ;

(2)Different reactions to fire:

For B1 grade fireproof aluminum composite sheet:

When B1 grade panels are put on fire, it can be catched on fire after 5 minutes, and the fire will extinguish after 10 seconds when the fire leave the panels.

A2 grade fireproof aluminium composite sheet:

It can be catched on fire after 20 minutes, and the fire will extinguish immediately when the fire leave the panels.

(3)Different testing indicators and requirements:

Testing indicators and requirements of B1 grade fireproof panels:

According to GB/T8625-88 test, the average residual length of each set of specimens ≥ 150mm, (the remaining length of each specimen> 0), and the average peak temperature of each test flue gas temperature ≤ 200 °C;

According to GB/T 8626-88 test, height index of flame tip <150mm, and the phenomenon of ignition of filter paper by burning drips is not allowed;

According to GB/T8627-1999 test, smoke density rating (SDR) ≤ 75.

Testing indicators and requirements of A2 grade fireproof panels:

According to GB/T 8625-88 test , the average residual length of each set of specimens ≥ 350mm (the remaining length of any specimen is > 200mm), and the peak value of the average flue gas temperature for each test ≤ 125° No burning phenomenon on the back of the specimen;

According to GB/T8627-1999 test, smoke density rating (SDR) ≤ 15;

According to GB/T14402-93 and GB/T14403-93 test, the thermal value of its material ≤ 4.2MJ/kg, the heat released per unit area of the test piece ≤ 16.8MJ/m2;

According to GA 132–1996, the total non-lethal concentration of Lco in flue gas toxicity of burning materials is greater than or equal to 25.0 mg/L, and the mice will not die within 3 days after exposure and their weight will be recovered.

The fireproof rating of aluminum composite panels is determined by two indicators, namely the national mandatory standard GB8624 "Building materials combustion performance classification method" and GB/T17748 "aluminum composite panel" national standard requirements. The combustion performance of building materials in China is graded as follows.

Class A: Non-combustible building materials

Class B1: Flame retardant building materials

Class B2: Combustible building materials

Class B3: Flammable building materials

The common core material of aluminum composite panel is low-density ordinary polyethylene, which will generate more smoke in the fire. Therefore, the fire-rated performance of aluminum composite panel has always been a focus of attention.

Aluminum Composite Panel After the Fire Are as Follows

In the fire, the aluminum composite panel itself did not burn. According to the test, the necessary condition for the combustion of the polyethylene core layer in the middle of the composite sheet is sufficient oxygen, and the polyethylene in the aluminum-plastic composite panel is not covered by the aluminum panel.

The glass next to the aluminum plate bursts and falls quickly after the fire. The aluminum-plastic composite board is still very strong, and the aluminum composite panel (including the pure aluminum board) will fall off only after reaching the melting point of aluminum.

Most fires start indoors. When the fire burns to the outdoor aluminum exterior wall, it will not pose a huge threat to personnel.

The above test and the analysis of the results are only manufacturer’s own point of view, but it is undeniable that when the aluminum composite panel is used for the curtain wall, the smoke generated by the polyethylene core material is less harmful due to diffusion and dilution.

Used in the case of interior decoration. Despite this, in order to be safe, many countries have restricted the use of common corealuminum composite panel. In high-rise buildings, aluminum-plastic composite panels are recommended to use non-combustible core materials.

In China, the state has put forward requirements for fire safety performance, especially for some crowded public places, such as airports, stations, stadiums, theaters, high-end entertainment venues and high-rise buildings, etc., the decorative materials selected must meet the fire protection requirements.

As a kind of new decorative material with wide application, aluminum composite panel attaches great importance to its fireproof performance. The National Fireproof Building Materials Quality Supervision and Inspection Center tests and classifies the fire safety performance of aluminum composite panel according to GB8624 “Classification Method of Combustion Performance of Building Materials”.

And the United Nations acp cladding quality supervision and inspection center, jointly implement the quality supervision of fire-resistant acm panels. The fireproof performance of mainly refers to the flame retardant performance of polyethylene plastic core board.

Due to the uniqueness of its chemical structure, most plastic products are flammable products. The relevant domestic units have developed safe and effective flame retardants for the combustion mechanism of polyethylene according to fire protection regulations, ensuring the technical performance of aluminum composite panels.

Under the premise, the fireproof performance of the acm materials meets the technical requirements of the nationally required combustion performance B1 grade, and creates conditions for mass production of fire-resistant aluminum composite panels for specific occasions.

According to the national standard “Code for Fire Protection of Building Design” (GBJ16), the wall material should be B1 (flammable material) or A (non-combustible material). The evaluation of the grade is in accordance with the national standard “Classification Method for Combustion Performance of Building Materials” (GB8624-1997). At present, the fireproof aluminum composite panel produced by most domestic enterprises has a fire rating of B1.

Certificate

Our Factory

We created our trading company Linyi Alux Import and Export Co.,Ltd. in 2018 , exported to the whole Asian, African countries ,Middle east, and the North and South America. With an annual export volume of 1.5 million US dollars, we are the largest Aluminum Composite Panel exporter in northern China.

FAQ

We're professional fireproof aluminum composite panel manufacturers and suppliers in China, specialized in providing high quality customized service. If you're going to buy discount fireproof aluminum composite panel in stock, welcome to get pricelist and free sample from our factory. Good service and low price are available.

Fireproof Aluminum Composite Panel, B1 Fireproof White ACP Sheet for Kitchen, Durability Fireproof ACP for Indoor Wall Decoration